Product Introduction

The 5X Series High-Efficiency Vertical Shaft Sand Making Machine is a new generation of crushing equipment developed to improve energy utilization, extend maintenance cycles, and reduce wear costs.

It integrates flexible feeding modes and has become the core equipment in the sand-making industry. It is widely used for producing various ores, cement, refractory materials, bauxite clinker, carborundum, and glass raw materials. It is especially effective for crushing hard and extra-hard materials like silicon carbide, emery, and sintered bauxite.

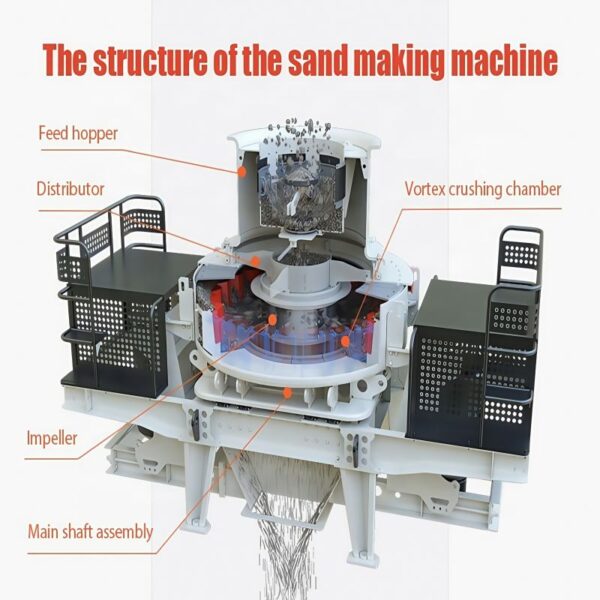

Working Principle

The 5X sand maker uses a high-speed rotor. Material enters the crusher and is divided into two parts by the distributor:

- Center Feeding: Part of the material enters the center of the high-speed impeller, is accelerated, and thrown out at high speed.

- Cascade Feeding: The other part of the material falls from around the impeller like a waterfall.

The two streams of material collide and crush each other (“Stone-hitting-Stone”), or impact against a metal anvil (“Stone-hitting-Iron”), depending on the configuration. This process ensures high-efficiency crushing and shaping with minimal wear to the machine body.

Key Features & Advantages

- Optimized Deep-Cavity Rotor:

The optimized rotor design increases material throughput compared to older VSI models, ensuring high efficiency. - Versatile Crushing Modes:

The machine supports flexible feeding adjustments (Center / Cascade) to suit different production capacity requirements. - Low Wear Design:

The optimized lower body structure prevents blockage when material moisture is high, and the “rock-on-rock” action minimizes metal wear, reducing operating costs. - Advanced Lubrication System:

Features a dual oil pump system (Thin Oil Lubrication Station) with automatic protection. It stops the machine if there is no oil flow or pressure, ensuring the safety of the bearings. - Mature & Reliable:

As a widely used model in the industry, the 5X series offers stable performance and easy availability of spare parts.

Technical Parameters

| Model | 5X7615 | 5X8522 | 5X9532 | 5X1145 | |

|---|---|---|---|---|---|

| Capacity (t/h) | Cascade and Center Feeding | 150 ~ 280 | 240 ~ 380 | 350 ~ 400 | 413 ~ 442 |

| Center Feeding | 70 ~ 140 | 120 ~ 200 | 180 ~ 280 | 250 ~ 360 | |

| Feeder Opening Size (mm) | Soft Material | 35 | 40 | 45 | 50 |

| Hard Material | 30 | 35 | 40 | 45 | |

| Rotation Speed (r/min) | 1700 ~ 1900 | 1500 ~ 1700 | 1300 ~ 1510 | 1100 ~ 1310 | |

| Power of the Double Motors (kw) | 110 ~ 150 | 180 ~ 220 | 260 ~ 320 | 400 ~ 440 | |

| Overall Dimension (mm) | 4100x2330x2300 | 4140x2500x2700 | 4560x2600x2900 | 5100x2790x3320 | |

| Power | 380V, 50Hz | ||||

| Thin oil lubrication station | Power of Double Oil Pump | 2 × 0.25Kw | |||

| Safety | Double oil pumps ensure supply; Auto-stop on no flow/pressure; Water cooled; Heating start in winter. | ||||

| Overall Dimension (mm) | 820 × 520 × 1270 | ||||

| Power of Oil-box Heater | 2Kw | ||||