Product Introduction

The 6X Series High-Efficiency Vertical Shaft Sand Making Machine is the newest, flagship crushing equipment from Xianglong Machinery. It builds upon the success of the 5X series but introduces groundbreaking structural innovations to maximize throughput and efficiency.

Unlike traditional vertical shaft impactors, the 6X series adopts a brand-new four-throwing port impeller design. This critical upgrade significantly increases material throughput, improving crushing efficiency by approximately 20% compared to three-port impellers working on the same material. It is the ideal solution for customers demanding the highest output and lowest operational costs in modern sand and gravel production.

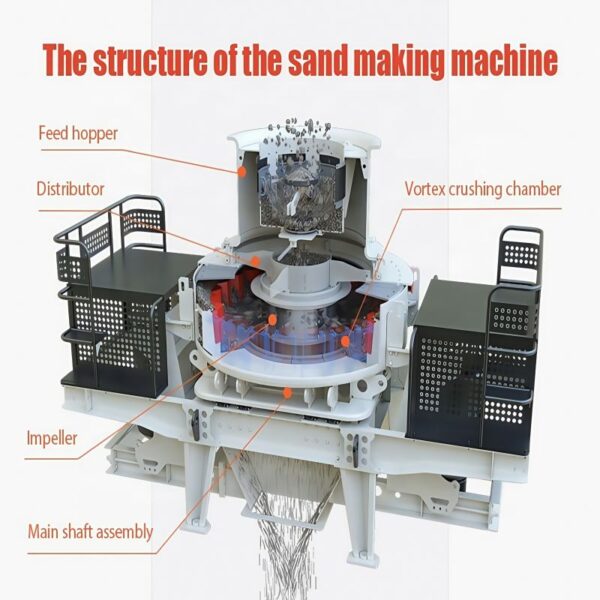

Working Principle

The 6X VSI operates on the principle of high-energy “Stone-hitting-Stone.” Material enters the high-speed rotor and is accelerated.

The Core Innovation: Instead of three exit ports, the 6X rotor features four throwing ports. This design allows a denser stream of material to be ejected at high velocity, impacting the surrounding material bed. This increases the probability of particle collision, resulting in finer crushing and better shaping efficiency per rotation. The material then falls freely to the bottom discharge.

Key Features & Advantages

- Revolutionary Four-Port Impeller:

The new four-port design allows for a massive increase in material throughput. Compared to traditional 3-port rotors, crushing efficiency is boosted by ~20%. - Hydraulic Lifting Device (Standard):

A newly added lifting device facilitates easy access to the rotor and internal components. This makes maintenance, inspection, and parts replacement convenient and safe, reducing downtime. - Anti-Clogging Lower Structure:

The simplified design of the lower machine body effectively prevents material blockage, especially when the moisture content of the raw material is high. - Enhanced Sealing & Imported Bearings:

The transmission part adopts a special sealing structure to strictly prevent oil leakage from the bearing barrel. High-quality imported bearings are used to reduce transmission system failures and ensure stability. - “Stone-Hitting-Stone” Efficiency:

The working mode minimizes wear on metal parts by using the rock itself to crush rock. This significantly reduces the types and quantity of wear-resistant parts needed, lowering production costs.

Technical Parameters

| Model | Feeding Size (mm) | Throughput (t/h) | Main shaft speed (r/min) | Power (kw) | ||

|---|---|---|---|---|---|---|

| Sand making | Sand Shaping | Sand making | Sand Shaping | |||

| VSI6X1263 | ≤50 | ≤60 | 454-486 | 545-583 | 900-1200 | 315 × 2 |

| VSI6X1150 | ≤45 | ≤55 | 344-368 | 413-442 | 1000-1300 | 250 × 2 |

| VSI6X1040 | ≤40 | ≤50 | 264-283 | 317-342 | 1100-1400 | 200 × 2 |

| VSI6X9026 | ≤35 | ≤45 | 167-179 | 200-215 | 1200-1500 | 132 × 2 |

| VSI6X8018 | ≤30 | ≤40 | 109-117 | 131-140 | 1300-1700 | 90 × 2 |