What exactly is a sand making machine and how does it function in aggregate production?

A sand making machine (or sand crusher) is a specialized crushing device designed to reduce large rocks into fine aggregates (0-5mm), known as manufactured sand (M-sand). These machines utilize impact or compression forces to shape and pulverize materials like granite, limestone, and river pebbles, serving as the final stage in crushing circuits for construction, highway, and concrete industries.

Comprehensive Classification: 5 Common Types of Sand Making Machines

What are the most common types of sand making machines available in the market today?

The primary types of sand making machines include the Vertical Shaft Impact (VSI) crusher, Double Roller crusher, Fine crusher (Third-Generation), Vertical Compound crusher, and the traditional Hammer/Impact crusher. While all these machines produce manufactured sand (0-5mm), they differ significantly in their structural design, intended material application, and production capacity.

To understand which machine fits your quarry, we must look at the specific role each plays in the aggregate production line.

VSI Sand Maker (Vertical Shaft Impact): The Industry Standard for Hard Rocks

The VSI Sand Making Machine is widely recognized as the most professional equipment for producing high-quality artificial sand. In the aggregate industry, it serves as the core shaping machine, often placed after the primary jaw crusher and secondary cone crusher.

Unlike other crushers that simply break rocks, the VSI focuses on particle shape. It produces sand with a cubical shape, which is essential for high-grade concrete. Flaky or needle-shaped particles, often produced by older compression crushers, reduce the flowability and compressive strength of concrete. The VSI eliminates this issue by knocking off sharp edges.

Key Characteristics:

- Material Suitability: Excellent for high-hardness materials like granite, basalt, and quartzite.

- Application: Large-scale aggregate plants, highway construction, and hydroelectric dam projects.

- Wear Parts: Uses carbide tips on the rotor. Note: The lifespan of these wear parts varies significantly based on silica content; precise wear estimates should be based on your specific rock analysis.

Double Roller Sand Maker: Economical Choice for Medium-Hardness Materials

The Double Roll Crusher operates on a different philosophy. Instead of high-speed impact, it relies on high pressure. Two wear-resistant rollers rotate toward each other, squeezing the material fed between them.

This machine is a favorite for small to medium-sized operations that need to control costs. Because it does not use high-speed impact, it produces less stone powder and dust compared to hammer mills. This feature is critical if your local environmental regulations are strict regarding dust emissions.

Best Applications:

- Materials: River pebbles, coal, and weathered rock. It struggles with extremely hard rock, which can damage the roller surface.

- Adjustability: You can control the size of the sand by mechanically adjusting the gap between the two rollers, utilizing a mechanism very similar to the discharge setting adjustment on a standard Jaw Crusher.

Fine Crusher (Third-Generation): High Efficiency for Soft Rocks like Limestone

The Fine Crusher, often called the “Third-Generation Sand Maker” in the industry, is a specialized modification of an impact crusher. It combines a heavy hammer head with a grating section (a grid-like screen) at the bottom.

This machine is highly efficient for brittle and soft materials. In a limestone quarry, a single Fine Crusher can sometimes replace the combination of a secondary impact crusher and a sand maker, simplifying the flow chart. However, strictly avoid using this machine for abrasive materials; feeding hard granite to a Fine Crusher will result in rapid hammer wear, making the operation economically unviable.

| Feature | Description |

|---|---|

| Structure | Integral hammerhead with adjustable discharge grating. |

| Efficiency | High throughput for soft rocks; typically 85% of output is sand. |

| Limitation | Not suitable for abrasive materials (Silica content > 5%). |

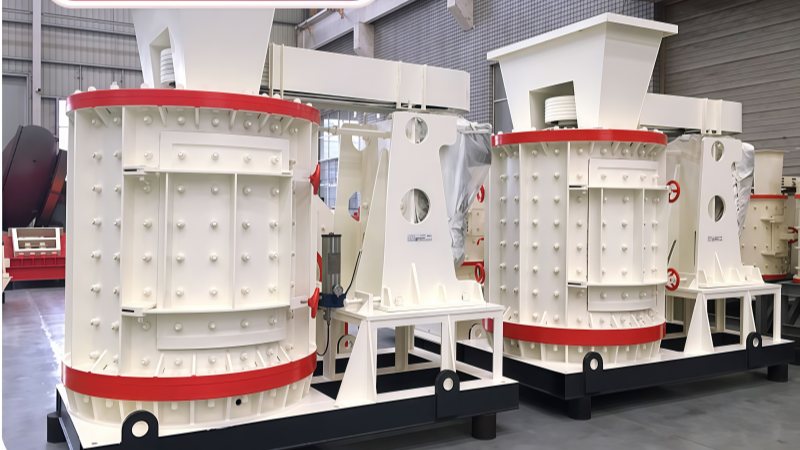

Vertical Compound Crusher: The Best Solution for High-Moisture Materials

The Vertical Compound Crusher addresses a specific operational headache: clogging. Many crushers fail when the raw material is wet or contains soil. The wet dust sticks to the screening plates, creating a blockage known as “blinding.”

The Compound Crusher solves this by having a vertical layout with no bottom screen plate. Gravity helps the material fall through directly. If you are processing raw coal or sandstone with high water content during the rainy season, this machine ensures continuous operation without downtime for cleaning.

Industry Context:

It is frequently used in cement plants to crush raw meal or clinker. It functions similarly to a primary gyratory crusher regarding vertical material flow, but is scaled down and adapted for fine crushing duties.

Hammer/Impact Crusher: Traditional Options for Small Scale Production

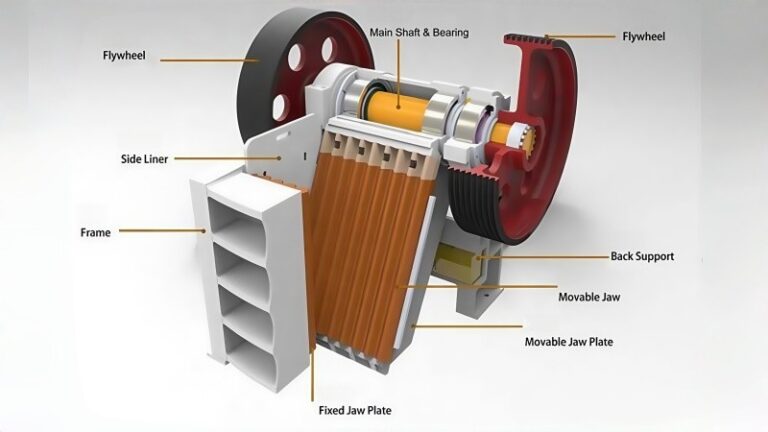

Before specialized VSI machines dominated the market, small hammer crushers and small impact crushers were the go-to solution for sand making. They are structurally simple, consisting of a rotor with hammers that smash rock against a liner.

While less common in modern large-scale plants, they remain popular for low-budget, small-scale setups. For example, a small brick factory or a mobile contractor might use a small hammer crusher to turn construction waste into usable fill sand.

Pros and Cons:

- Advantage: Extremely low initial purchase cost and easy maintenance.

- Disadvantage: The finished sand often has micro-cracks, and the output shape is not as consistent as VSI sand. Additionally, hammer wear is rapid, requiring frequent replacement.

Comparative Analysis: Differences in Working Principles

How do the internal mechanics of sand making machines differ in crushing rock into fine aggregates?

The working principles of sand making machines fundamentally differ based on how force is applied: impact energy versus compression force. Impact machines, such as VSI and Fine Crushers, utilize high-speed rotors to throw or strike rocks against hard surfaces to shatter them. In contrast, compression machines, like Roller Crushers, apply steady pressure to squeeze rocks until they fracture, resulting in different particle shapes and powder concentrations.

Understanding these mechanical distinctions is crucial for predicting maintenance needs and product quality.

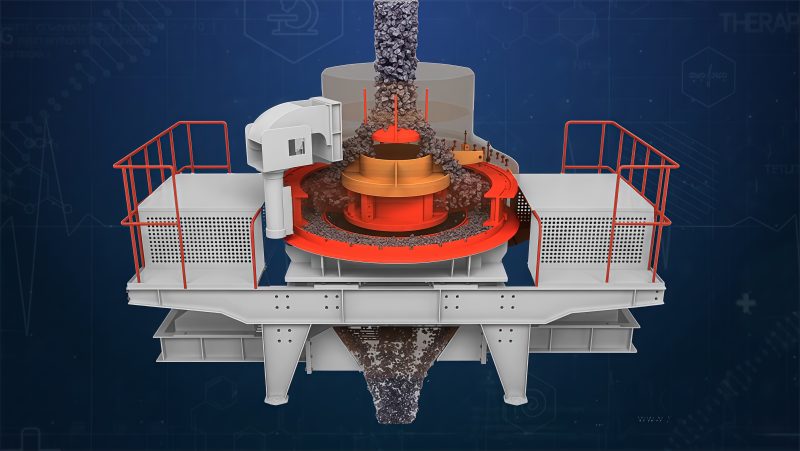

Stone-on-Stone vs. Stone-on-Iron: Understanding Impact Methods (VSI)

The Vertical Shaft Impact (VSI) crusher is unique because it offers two distinct crushing modes within the same machine structure. These modes dictate how the rock is broken after it leaves the high-speed rotor.

Stone-on-Stone (Autogenous Crushing):

In this mode, the machine does not throw rock against a steel liner. Instead, a “material bed” or lining of rocks forms naturally around the perimeter of the crushing chamber. The high-speed particles ejected from the rotor collide with this static layer of rocks.

- Mechanism: Rock collides with rock.

- Result: This action provides excellent shaping (cubical particles) rather than massive size reduction. It mimics the geological erosion process found in riverbeds but at a highly accelerated rate. Because the rock hits other rocks, abrasive wear on the metal body is minimized.

Stone-on-Iron (Anvil Crushing):

Here, the material bed is replaced with steel anvil plates. The rotor throws the rock directly against these metal blocks.

- Mechanism: Rock collides with metal.

- Result: This delivers higher crushing efficiency (high sand output ratio). However, it causes significant wear on the peripheral liners.

| Crushing Mode | Collision Target | Primary Function | Wear Cost |

|---|---|---|---|

| Stone-on-Stone | Self-lined Rock Bed | Reshaping & Polishing | Low |

| Stone-on-Iron | Metal Anvil Plates | Size Reduction (Sand Making) | High |

Squeezing vs. Striking: Why Roller Machines Produce Less Powder

The fundamental difference between a Roller Sand Maker and an Impact machine lies in the physics of fracture.

Striking (Impact Mechanics):

VSI and Hammer crushers rely on high kinetic energy. The rotor strikes the stone at speeds often exceeding 60-70 meters per second. This high-velocity impact causes the rock to explode along natural fissures. While effective, this violent action creates a high volume of “micro-fines” or stone powder (often >15-20%). It is comparable to the difference between blasting a rock face with explosives versus drilling it; the explosive force creates significantly more dust.

Squeezing (Compression Mechanics):

Double Roller machines operate like a Secondary Cone Crusher but with a tighter gap setting. The rollers pull the material in and apply gradual pressure until the rock’s structural integrity fails.

- Mechanism: The rock cracks cleanly.

- Result: This process produces relatively coarse sand with very low powder content. It avoids the “over-crushing” phenomenon common in high-speed impactors. If your project requires a strict limit on the percentage of material passing the 0.075mm sieve, the squeezing principle offers a mechanical advantage.

Grating vs. Hammering: Discharge Differences in Fine and Compound Crushers

Although Fine Crushers and Compound Crushers are both widely used for processing soft rocks, their internal discharge structures are fundamentally different.

The Grating Barrier (Fine Crusher):

The Fine Crusher (Third-Generation) features a physical barrier—a grate or screen plate—at the bottom discharge point.

- Process: The hammerhead strikes the rock repeatedly within the chamber. The material cannot leave the machine until it is small enough to pass through the grate slots.

- Consequence: This ensures a guaranteed top size for the output. However, if the material is wet, it will paste over the grate holes, blocking the discharge path immediately.

Gravity Discharge (Compound Crusher):

The Compound Crusher operates without a bottom grate. It relies purely on gravity and the geometry of the rotor to clear material.

- Process: Material is crushed between the rotor and the liner, then falls vertically out of the machine.

- Consequence: Since there is no physical sieve to hold the material back, wet or sticky material passes through easily. However, without the grate to force repeated crushing, the output size can be less uniform compared to the Fine Crusher, occasionally allowing larger flakes to pass through.

Selection Guide: How to Choose the Right Machine for Your Project

What are the critical factors you must evaluate to select the correct sand making machine for your specific quarry?

To choose the right sand making machine, you must primarily analyze the hardness and abrasiveness of your raw material, calculate the balance between your initial purchase budget and long-term maintenance costs, and determine your required hourly production output. While VSI crushers are essential for hard, abrasive rocks to prevent rapid wear, simpler impact or roller machines offer cost-effective solutions for softer materials and smaller operations.

Making the wrong choice here can lead to skyrocketing operational costs or equipment failure.

Based on Material Hardness: Why Granite Needs VSI and Limestone Can Use Fine Crushers

The most critical technical parameter in selection is the Mohs hardness and Silicon Dioxide (SiO2) content of your stone. Hardness determines how difficult the rock is to break, while silica content determines how abrasive it is to the metal liners.

High Abrasiveness (Granite, Basalt, River Pebble):

If you are processing material with high silica content (usually above 10-15%), you must use a VSI Sand Maker.

- Reasoning: High-silica rocks act essentially like industrial sandpaper on metal. If you use a Fine Crusher or Hammer Crusher on granite, the heavy hammerheads will wear out in just a few days or even shifts due to the gouging action.

- Industry Insight: The VSI uses the “Stone-on-Stone” lining mentioned earlier. Because the rock impacts other rocks rather than metal, the machine body is protected from this intense abrasion.

Low Abrasiveness (Limestone, Coal, Gypsum):

For soft rocks (Mohs hardness < 4-5), a Fine Crusher (Third-Generation) or Double Roller is often the smarter choice.

- Reasoning: Soft rocks do not wear down hammerheads quickly. Therefore, you can take advantage of the high-efficiency “grating” or “squeezing” mechanics of these machines without worrying about excessive maintenance costs.

Based on Input Budget: Balancing High Initial Cost vs. High Wear Part Cost

Every quarry owner faces the trade-off between Capital Expenditure (CAPEX) and Operating Expenditure (OPEX). You must decide if you want to pay more now or pay more later.

The “Pay Now” Approach (VSI Crusher):

- Initial Cost: High. VSI machines require larger motors and complex rotor balancing systems.

- Operating Cost: Low (for hard rocks). Since the rock lines the chamber, you buy fewer metal liners over time.

- Best For: Long-term projects (3+ years) where low daily running costs justify the expensive machine.

The “Pay Later” Approach (Hammer/Fine/Impact Crusher):

- Initial Cost: Low. The structure is simple—just a rotor, a casing, and a motor.

- Operating Cost: High. You will replace hammerheads and blow bars frequently.

- Best For: Short-term projects, temporary sites, or processing soft materials where wear is negligible.

| Machine Type | Initial Purchase Price | Wear Part Replacement Frequency | Ideal Financial Strategy |

|---|---|---|---|

| VSI Crusher | $$$ (High) | Low (Months) | Long-term Investment |

| Fine Crusher | $$ (Medium) | Medium (Weeks/Months) | Balanced Approach |

| Hammer Crusher | $ (Low) | High (Days/Weeks) | Low Budget Start-up |

Note: Prices and wear life fluctuate based on local steel prices and specific supplier technology.

Based on Production Scale: Matching Machine Capacity to Your Quarry Output

Finally, you must match the machine size to your production line’s throughput (Tons Per Hour – TPH). Using a machine that is too big wastes electricity, while one that is too small causes bottlenecks.

Large Scale (> 100 TPH):

For commercial aggregate plants supplying concrete batching stations, the VSI Sand Maker is the standard.

- Throughput: VSI units are designed for high speed and volume. A single large VSI can process hundreds of tons per hour.

- Efficiency: It handles the massive flow from primary jaw crushers efficiently. Attempting to use multiple small Roller crushers to match one VSI’s output would create a maintenance nightmare due to the number of motors and belts involved.

Small to Medium Scale (< 50 TPH):

For small brick plants or village-level quarries, Compound Crushers or Double Roller Machines are superior.

- Efficiency: These machines consume less power per ton at lower volumes. Running a 200kw VSI motor to produce just 20 tons of sand per hour is economically wasteful due to the high “no-load” energy consumption.

- Setup: These smaller units often do not require the heavy concrete foundations that a VSI requires, making them easier to install for smaller operations.

Conclusion

Selecting the right sand making machine is not just about buying hardware; it is about matching technology to your specific geology and business model.

If you are dealing with hard granite and require top-tier concrete aggregate, the VSI Sand Maker is the undisputed choice despite the higher initial cost. For soft limestone or coal, Fine Crushers and Double Rollers offer efficient, budget-friendly alternatives. By carefully evaluating your material properties, budget, and required output, you can ensure your production line runs efficiently and profitably.