Product Introduction

The VSI High-Efficiency Vertical Shaft Sand Making Machine is a high-performance sand making machine developed by Xianglong Machinery. Combining advanced German technology with China’s working conditions, this machine is a world leader in producing high-grade manufactured sand and gravel aggregates.

It is the preferred equipment for producing premium aggregates for highways, high-speed railways, civil engineering, and concrete mixing stations. The VSI series is renowned for its large processing capacity, stable operation, low consumption of wearing parts, excellent product particle shape (cubic), and advanced thin oil lubrication system.

Typical Applications

This Vertical Shaft Impactor (VSI) is expertly designed for:

- Manufactured Sand Production: Creating high-quality, well-graded artificial sand to replace natural sand.

- Aggregate Shaping: Reshaping and cubing flaky or elongated aggregates from primary and secondary crushers.

- High-Grade Aggregate: Producing premium aggregates for concrete, asphalt, and high-speed railway ballast.

- Mineral Crushing: Fine crushing in mining operations, handling materials like iron ore, granite, and basalt.

Core Features

- Excellent Particle Shape

The VSI utilizes “rock-on-rock” and “rock-on-iron” crushing principles, resulting in a superior, cubic particle shape that is ideal for high-specification concrete. - Large Processing Capacity

With a deep-cavity rotor design and optimized feed modes (Center Feeding and Cascade Feeding), this machine achieves a significantly higher throughput (60-520 t/h) compared to traditional sand makers. - Low Wear & Maintenance Cost

Strategic design minimizes wear on key components. Equipped with an advanced thin oil lubrication station and vibrating sensor, the system is reliable and reduces downtime. - Advanced Lubrication System

The double oil pump system ensures a continuous, reliable oil supply. It features automatic stop protection (if no oil flow or pressure) and a water-cooling system for stable operation in hot conditions. - Automatic Monitoring

Equipped with a vibrating sensor (inspection scope: 0.1-20mm/s), the machine can be monitored continuously, ensuring operational safety.

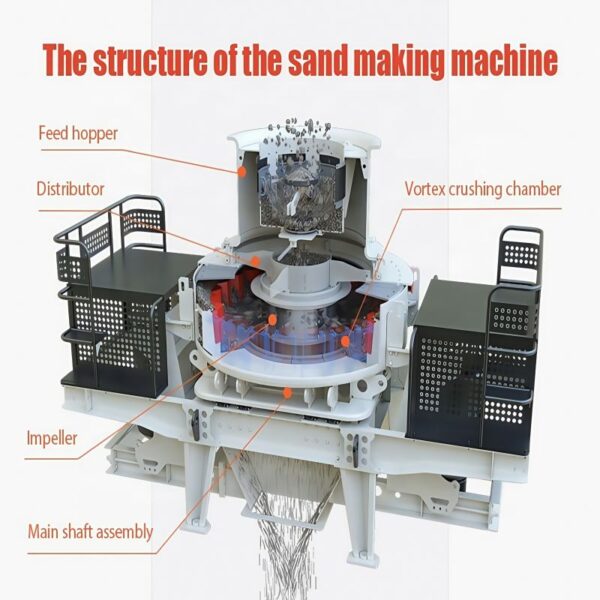

Working Principle

The VSI Sand Making Machine operates on a high-speed centrifugal principle. Material enters the center of the high-speed spinning rotor and is accelerated to 1180-1890 r/min. It is then violently ejected from the rotor and collides with:

- Rock-on-Rock: Ejected material collides with a cascade of material lining the crushing chamber. This is best for shaping and for highly abrasive materials.

- Rock-on-Iron: Ejected material collides with a metal anvil ring in the crushing chamber. This is best for maximum crushing and production.

This high-impact process breaks the material along its natural fissure lines, producing a high-quality, cubic-shaped product.

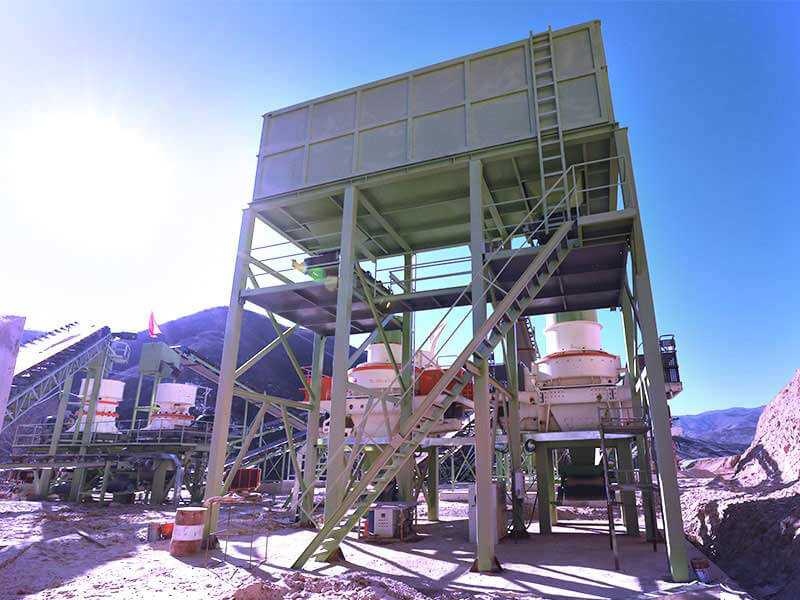

Product Photos

Technical Parameters

| Model | VSI-7611 | VSI-8518 | VSI-9526 | VSI-1140 | |

|---|---|---|---|---|---|

| Capacity (t/h) | Cascade and Center Feeding | 120-180 | 200-260 | 300-380 | 450-520 |

| Center Feeding | 60-90 | 100-130 | 150-190 | 225-260 | |

| Feeder Opening Size (mm) | Soft Material | ≤35 | ≤40 | ≤45 | ≤50 |

| Hard Material | ≤30 | ≤35 | ≤40 | ≤45 | |

| Rotation Speed (r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | |

| Power of the Double Motors(kw) | 110-150 | 180-220 | 264-320 | 400-440 | |

| Overall Dimension (mm) | 3700x2150x2100 | 4140x2280x2425 | 4560x2447x2778 | 5000x2700x3300 | |

| Weight (t) | 7.8 | 10.3 | 16 | 25.6 | |

| Power | 380V:50Hz | ||||

| Vibrating Sensor | Inspection Scope: 0.1-20mm/s, it can be adjusted continuously | ||||

| Thin oil lubrication station | Power of Double Oil Pump | 2 x 0.31KW | |||

| Safety | Double oil pumps make sure supply of oil; Stop automatically without oil flow or oil pressure; Water cooled; Heating start the motor in winter | ||||

| Overall Dimension (mm) | 820 x 520 x 1270 | ||||

| Heater Power(kw) | 2KW | ||||