Product Introduction

The Ball Mill is the key equipment for re-grinding (fine grinding or pulverizing) materials after they have been primarily crushed. It is an essential and highly versatile grinding mill used across numerous industries for achieving the required product fineness.

Xianglong Machinery’s ball mills are engineered for reliability and efficiency. They are widely used for either dry type or wet type grinding of all kinds of ores and other grindable materials in industries such as cement, silicate products, new building materials, refractory materials, fertilizer, black and non-ferrous metal ore dressing (mining), and glass ceramics production.

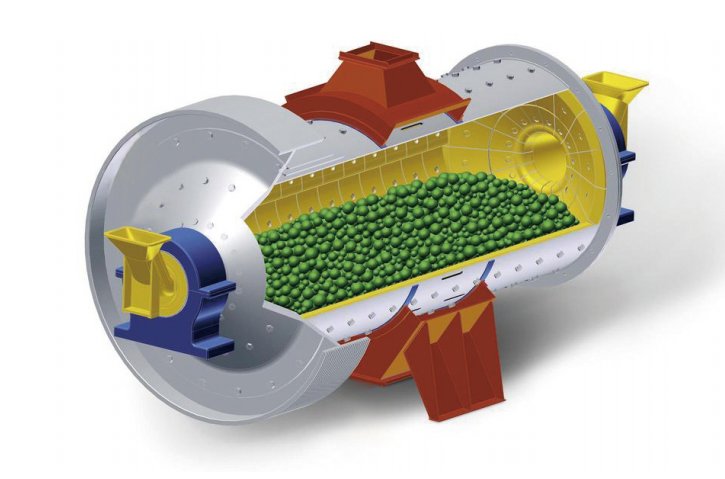

Working Principle

The ball mill operates through rotation, causing the grinding media (steel balls) inside the cylindrical shell to cascade and tumble. Material fed into the mill is crushed and ground through impact (balls falling onto the material) and attrition (material rubbing between the balls and against the mill liners).

As the shell rotates, lifter bars inside help lift the balls. Depending on the rotation speed, the balls cascade down, creating the grinding action. The finely ground material is then discharged from the mill through discharge openings, often controlled by a grate or overflow system, depending on whether it’s a wet or dry grinding process.

Key Features & Advantages

- Versatile Grinding: Suitable for both wet and dry grinding applications across a vast range of materials.

- High Grinding Efficiency: Optimized design ensures efficient particle size reduction to meet product specifications.

- Wide Range of Models: Offers a comprehensive selection of sizes (from 900×1800 to 5500×8500) and capacities (0.65 t/h up to 615 t/h) to suit various production scales.

- Durable Construction: Built with high-quality materials for long service life and reliable operation in demanding industrial environments. (Liners and grinding media available in various materials to suit application needs).

- Stable Performance: Smooth operation with robust bearing support and reliable drive systems.

- Wide Applicability: Proven performance in numerous industries requiring fine grinding.

Common Applications

- Cement Industry: Grinding clinker and gypsum to produce finished cement.

- Mining Industry: Grinding various ores (gold, copper, iron, etc.) for mineral liberation before beneficiation.

- Building Materials: Producing fine powders for silicate products, new building materials, bricks, etc.

- Refractory Materials: Grinding raw materials for refractory products.

- Chemical & Fertilizer: Grinding various chemical raw materials and phosphate rock.

- Glass & Ceramics: Preparing raw materials requiring fine particle sizes.

Product photos

Technical Parameters

| Model | Shell Rotation Speed (r/min) | Ball Load (t) | Feeding Size (mm) | Discharging Size(mm) | Capacity (t/h) | Motor Power(kw) | Total Weight(t) |

|---|---|---|---|---|---|---|---|

| Φ900 x 1800 | 36 | 1.5 | ≤20 | 0.075-0.89 | 0.65 – 2 | 18.5 | 5.5 |

| Φ900 x 3000 | 38 | 2.7 | ≤20 | 0.075-0.89 | 1.1 – 3.5 | 22 | 6.7 |

| Φ1200 x 2400 | 36 | 3 | ≤25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 |

| Φ1200 x 3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

| Φ1200 x 4500 | 36 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

| Φ1500 x 3000 | 32.4 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 | 16.8 |

| Φ1500 x 4500 | 29.7 | 11 | ≤25 | 0.074-0.4 | 3-6 | 110 | 21 |

| Φ1500 x 5700 | 27 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| Φ1830 x 3000 | 25.4 | 11 | ≤25 | 0.074-0.4 | 4 – 10 | 130 | 29 |

| Φ1830 x 4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 4.5 – 12 | 155 | 35.5 |

| Φ1830 x 6400 | 24.1 | 21 | ≤25 | 0.074-0.4 | 6.5 – 15 | 210 | 43 |

| Φ1830 x 7000 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.5 – 17 | 245 | 43.8 |

| Φ2100 x 3000 | 23.7 | 15 | ≤25 | 0.074-0.4 | 6.5 – 36 | 155 or 180 | 34.8 |

| Φ2100 x 4500 | 23.7 | 24 | ≤25 | 0.074-0.4 | 8 – 43 | 245 | 42 |

| Φ2100 x 7000 | 23.7 | 26 | ≤25 | 0.074-0.4 | 8 – 48 | 280 | 56.6 |

| Φ2200 x 4500 | 21.5 | 27 | ≤25 | 0.074-0.4 | 9 – 45 | 280 | 51.8 |

| Φ2200 x 6500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 14-26 | 380 | 60 |

| Φ2200 x 7000 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 | 62 |

| Φ2200 x 7500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 | 64.8 |

| Φ2400 x 3000 | 21 | 23 | ≤25 | 0.074-0.4 | 7 – 50 | 245 | 58 |

| Φ2400 x 4500 | 21 | 30 | ≤25 | 0.074-0.4 | 8.5-60 | 320 | 69 |

| Φ2700 x 4000 | 20.7 | 40 | ≤25 | 0.074-0.4 | 12-80 | 400 | 94 |

| Φ2700 x 4500 | 20.7 | 48 | ≤25 | 0.074-0.4 | 12-90 | 480 | 102 |

| Φ3200 x 4500 | 18 | 65 | ≤25 | 0.074-0.4 | Based on process conditions | 630 | 137 |

| Φ3600 x 4500 | 17 | 90 | ≤25 | 0.074-0.4 | Based on process conditions | 1000 | 158 |

| Φ3600 x 6000 | 17 | 110 | ≤25 | 0.074-0.4 | Based on process conditions | 1250 | 175 |

| Φ3600 x 8500 | 18 | 131 | ≤25 | 0.074-0.4 | 45.8 – 256 | 1800 | 252 |

| Φ4000 x 5000 | 16.9 | 121 | ≤25 | 0.074-0.4 | 45 – 208 | 1500 | 203 |

| Φ4000 x 6000 | 16.9 | 146 | ≤25 | 0.074-0.4 | 65 – 248 | 1600 | 218 |

| Φ4000 x 6700 | 16.9 | 149 | ≤25 | 0.074-0.4 | 45 – 252 | 1800 | 238 |

| Φ4500 x 6400 | 15.6 | 172 | ≤25 | 0.074-0.4 | 54 – 306 | 2000 | 280 |

| Φ5030 x 6400 | 14.4 | 216 | ≤25 | 0.074-0.4 | 68 – 386 | 2600 | 320 |

| Φ5030 x 8300 | 14.4 | 286 | ≤25 | 0.074-0.4 | 88 – 500 | 3300 | 403 |

| Φ5500 x 8500 | 13.8 | 338 | ≤25 | 0.074-0.4 | 108 – 615 | 4500 | 525 |