Product Introduction

The Circular Vibrating Screen utilizes an eccentric shaft vibration exciter and partial block mechanism to adjust amplitude, resulting in a circular motion of the screen box. This design ensures a long material screening line with many specifications and clear screening for different sizes.

It features a strong exciting force, high screening efficiency, low noise, convenient maintenance, a safe operation structure, etc. This utility model is widely used in product classification within industries such as mining, quarrying, building materials, transportation, energy, and chemical processing. The model has advantages like strong excitation force, simple structure, convenient maintenance, stable operation, large processing capacity, long service life, and low noise.

Working Principle

The motor drives the eccentric shaft vibration exciter via a V-belt, causing the screen box to vibrate with a circular trajectory. Due to the impulse generated by the screen box’s vibration, materials on the inclined screen surface are continuously thrown, layered, and passed through the mesh openings. Particles smaller than the sieve pore size pass through the screen (undersize), while larger particles remain on the screen surface (oversize) and are discharged from a different outlet, thus achieving material classification.

Key Features & Advantages

- High Screening Efficiency & Productivity:

Due to the strong vibration of the screen box, the phenomenon of material blocking the screen holes is significantly reduced, resulting in high screening efficiency and productivity. - Strong & Stable Excitation Force:

Utilizes an eccentric shaft vibration exciter for powerful and reliable vibration. - Adjustable Amplitude:

Partial block mechanism allows for easy amplitude adjustment to suit different material requirements. - Compact & Easy Maintenance:

Features a simple structure. Modular vibration exciters on both sides of the screen box can be disassembled as a whole and replaced quickly, eliminating the tedious process of replacing bearings alone. - Energy Saving:

The motor is directly connected to drive, reducing the energy consumption of the transmission system. - Durable & Long Service Life:

Robust construction ensures stable operation and longevity even under demanding conditions. - Low Noise Operation:

Designed for reduced operational noise levels. - Environmental Options:

Optional spray system and sealing/dustproof system can be added for enhanced environmental protection.

Common Applications

- Aggregate Classification: Sizing crushed stone, sand, and gravel in quarries and aggregate plants.

- Mining Operations: Screening various ores and minerals after crushing stages.

- Building Materials: Classifying raw materials for cement, concrete, etc.

- Chemical Industry: Sizing various chemical products.

- Coal Preparation: Screening and classifying coal.

- Recycling: Separating different fractions of recycled materials.

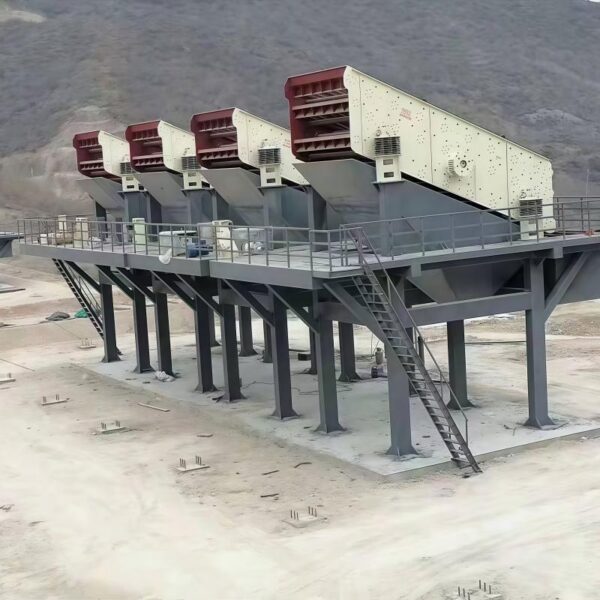

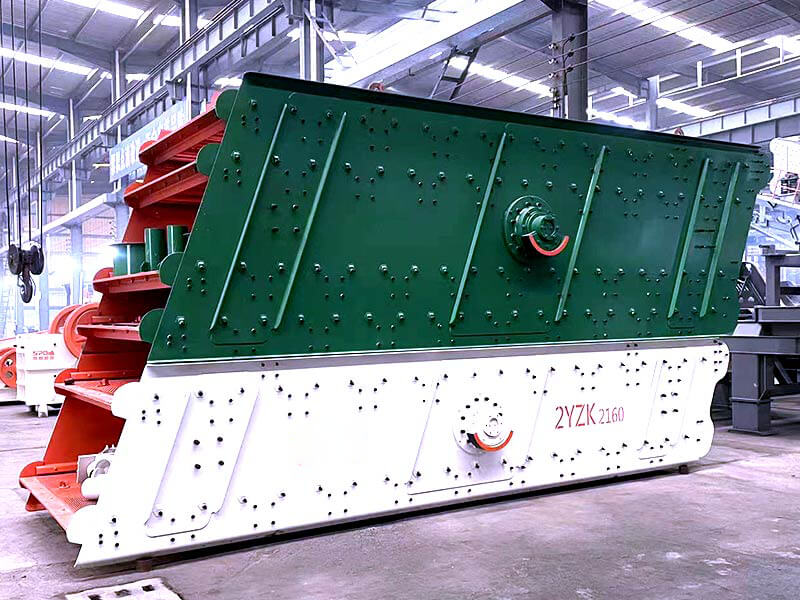

Product Photos

Technical Parameters

| Model | Screen Surface Specification (mm) | Layers | Sieve Pore Size(mm) | Feeding Size (mm) | Capacity (t/h) | Power (kw) | Vibrating Frequency (r/min) | Stroke (mm) |

|---|---|---|---|---|---|---|---|---|

| 2YZK1237 | 3700 x 1200 | 2 | ≤400 | 3-50 | 30-100 | 5.5 | 970 | 5-9 |

| 3YZK1237 | 3700 x 1200 | 3 | ≤400 | 3-50 | 30-100 | 7.5 | 970 | 5-9 |

| 2YZK1548 | 4800 x 1500 | 2 | ≤400 | 3-100 | 30-275 | 15 | 970 | 5-9 |

| 3YZK1548 | 4800 x 1500 | 3 | ≤400 | 3-100 | 30-275 | 15 | 970 | 5-9 |

| 2YZK1848 | 4800 x 1800 | 2 | ≤400 | 3-100 | 56-330 | 18.5 | 970 | 5-9 |

| 3YZK1848 | 4800 x 1800 | 3 | ≤400 | 3-100 | 56-330 | 18.5 | 970 | 5-9 |

| 4YZK1848 | 4800 x 1800 | 4 | ≤400 | 3-80 | 56-330 | 22 | 970 | 5-9 |

| 2YZK1860 | 6000 x 1800 | 2 | ≤400 | 3-100 | 65-586 | 18.5 | 970 | 5-9 |

| 3YZK1860 | 6000 x 1800 | 3 | ≤400 | 3-100 | 65-586 | 22 | 970 | 5-9 |

| 4YZK1860 | 6000 x 1800 | 4 | ≤400 | 3-100 | 65-586 | 30 | 980 | 5-9 |

| 2YZK2160 | 6000 x 2100 | 2 | ≤400 | 3-100 | 81-720 | 22 | 980 | 5-9 |

| 3YZK2160 | 6000 x 2100 | 3 | ≤400 | 3-100 | 81-720 | 30 | 970 | 5-9 |

| 4YZK2160 | 6000 x 2100 | 4 | ≤400 | 3-100 | 81-720 | 30 | 980 | 5-9 |

| 2YZK2460 | 6000 x 2400 | 2 | ≤400 | 3-150 | 100-810 | 22 | 970 | 5-9 |

| 3YZK2460 | 6000 x 2400 | 3 | ≤400 | 3-150 | 100-810 | 30 | 980 | 5-9 |

| 4YZK2460 | 6000 x 2400 | 4 | ≤400 | 3-150 | 150-850 | 37 | 980 | 5-9 |

| 2YZK2870 | 7000 x 2800 | 2 | ≤400 | 5-100 | 120-680 | 22 x 2 | 750 | 8 |

| 3YZK2870 | 7000 x 2800 | 3 | ≤400 | 5-100 | 180-720 | 22 x 2 | 750 | 8 |

| 2YZK3070 | 7000 x 3000 | 2 | ≤400 | 5-100 | 200-700 | 37 | 750 | 8 |

| 3YZK3070 | 7000 x 3000 | 3 | ≤400 | 5-100 | 230-800 | 45 | 750 | 8 |