So, what is a stone crusher and how does it all work?

A stone crusher is a heavy-duty machine that breaks large rocks into smaller pieces like gravel or sand. It works using two main principles: compression (squeezing the rock) or impact (striking it). The main types include Jaw, Cone, Gyratory, HSI, and VSI crushers, each used at different stages in a “crusher plant” to produce aggregates for construction.

What is a Stone Crusher?

You might be wondering, what exactly is a stone crusher?

A stone crusher is a heavy-duty machine designed to take large, solid rocks and break them down into smaller, more manageable pieces, such as gravel, sand, or rock dust. It serves as the primary size-reduction equipment in mining, construction, and recycling operations, processing raw materials like granite, limestone, and concrete rubble.

The goal isn’t just to smash rocks randomly. The purpose is to produce specific, desired sizes of output material. These machines are engineered for power and durability, capable of handling extremely hard and abrasive materials day in and day out.

In a typical operation, large rocks are fed into the crusher. The machine then applies immense force to reduce them. The resulting smaller pieces are then sorted or sent for further processing. This initial breakdown is often called primary crushing, and it’s the first and most critical step in transforming useless, oversized boulders into valuable resources.

Why Are Stone Crushers Essential to Modern Society?

Now that we know what a crusher is, why is it so important? You can’t overstate their importance. Stone crushers work behind the scenes, turning massive, useless rock into the basic materials for everything we build.

The Bedrock of Construction and Infrastructure

Look around you. The concrete in your house, the asphalt on the roads you drive on, and the foundations of bridges and skyscrapers all start as large rocks. Stone crushers are essential because they produce the primary ingredient for this concrete and asphalt, known as aggregate.

Without crushers, we would have no cost-effective way to create the specific sizes of crushed stone needed to build:

- Roads and Highways: The base layer (sub-base) that provides stability and the asphalt itself are made almost entirely of crushed aggregate.

- Concrete: This is simply a mix of cement (a binder), water, and aggregates (sand and gravel). Every sidewalk, dam, and building relies on it.

- Railways: The ballast—the bed of stones that supports the railway ties—is a key crusher product that provides drainage and stability for train tracks.

Driving Mining and Resource Extraction

In the mining industry, valuable ores (like iron, copper, or gold) are often trapped inside massive, worthless rock formations.

A stone crusher is the first step in liberation. It breaks down the large ore-bearing rock, freeing the valuable minerals. After crushing, these smaller pieces are sent to grinding mills (which we’ll discuss later) to be turned into a fine powder. From this powder, the valuable metals that power our electronics and build our cities can be separated.

Powering Environmental Sustainability

Stone crushers also play a critical role in recycling. Old, demolished concrete from buildings and broken-up asphalt from road repairs are not just waste.

These materials can be fed into a crusher to create Recycled Concrete Aggregate (RCA). This recycled material can then be used in new construction projects, often as a high-quality base layer for new roads. This process:

- Reduces the amount of waste sent to landfills.

- Conserves natural resources by reducing the need to quarry new rock.

- Lowers the environmental footprint and cost of the construction industry.

In short, the stone crusher is a fundamental industrial machine. It performs the essential job of turning massive, unusable rock into the specific, high-quality materials we need for all construction.

How Does a Rock Crusher Work? The 2 Core Principles

So, how does a machine actually break solid rock?

A rock crusher works by applying intense mechanical force to a rock, creating stress that exceeds its breaking point. This force is delivered through two primary methods: compression, which squeezes the rock until it shatters, or impact, which strikes the rock with a high-speed blow.

Every stone crusher you will see—from the massive primary units in a quarry to the mobile machines on a recycling site—uses one or both of these simple, powerful principles. The method a machine uses is directly related to its job. This includes the type of rock it needs to break (is it hard granite or soft limestone?) and the final product size required (is the goal to make large gravel or fine sand?).

Principle 1: Compression Crushing

Compression is the most common and oldest method of crushing.

Think of this as squeezing the rock.

In a compression crusher, the material is pinched and broken between two solid, wear-resistant surfaces. One surface is typically fixed (called a stationary liner), while the other (a moving liner) presses against it.

The process works like this:

- A large rock falls into a chamber.

- A moving component slowly increases the pressure on the rock, pinning it against the stationary wall.

- The force builds up inside the rock.

- Once the pressure is greater than the rock’s “compressive strength,” it cracks and shatters into smaller pieces.

This method is ideal for very hard and abrasive materials, like granite or basalt. Because the action is slow and controlled, it minimizes the wear and tear on the machine’s metal parts, which is a major cost factor in quarry operations.

Compression crushing is the main principle used in primary crushing (breaking the largest boulders) and secondary crushing (breaking those pieces down further). As we’ll see in the next section, Jaw, Gyratory, and Cone crushers all operate using this principle.

Principle 2: Impact Crushing

The second method, impact, is exactly what it sounds like. Instead of a slow squeeze, this is a fast, violent strike.

Think of this as hitting the rock with a sledgehammer.

In an impact crusher, the material is not slowly squeezed. Instead, it is struck by a component (like a “blow bar” or “hammer”) moving at very high speed. This sudden, dynamic force transfers a huge amount of energy to the rock, causing it to shatter.

In many designs, the machine also throws the rock at high velocity against a solid, stationary wall (called a “breaker plate”), causing it to break even further upon impact.

This method is preferred for several reasons:

- Better Shaping: It tends to break rocks along their natural lines of weakness, which often results in a more uniform, cubical (square-shaped) product. This is highly desired for making high-quality concrete and asphalt.

- Material Type: It is best suited for softer, less abrasive materials like limestone, phosphate, or in recycling applications like crushing old concrete and asphalt. Using it on very hard granite would cause the hammers to wear down extremely quickly.

- Product Size: Impactors are excellent at creating smaller products, including manufactured sand.

This principle is the engine behind HSI (Horizontal Shaft Impact) and VSI (Vertical Shaft Impact) crushers.

To make the difference clear, here is a simple comparison:

| Feature | Compression Crushing | Impact Crushing |

|---|---|---|

| Action | Squeezing / Pressing | Striking / Hitting |

| Speed | Slow and steady | Fast and dynamic |

| Best ForExample | Hard, abrasive materials (e.g., granite, basalt) | Softer, less abrasive materials (e.g., limestone, concrete) |

| Main Product | Good cubical shape, fewer fine particles | Excellent cubical shape, more fine particles (sand) |

| Primary Use | Primary and secondary crushing (breaking big rocks) | Secondary and tertiary crushing (shaping, sand making) |

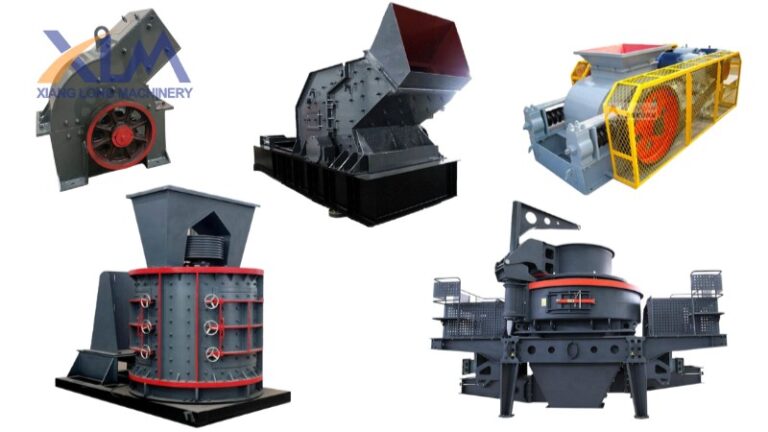

The 5 Main Types of Stone Crushers (Your Sizing Guide)

So, what are the main types of crushers used in the industry?

While there are many specialized designs, the industry relies on five main types of stone crushers: Jaw Crushers, Gyratory Crushers, Cone Crushers, Horizontal Shaft Impact (HSI) Crushers, and Vertical Shaft Impact (VSI) Crushers. Each is designed for a specific stage of crushing and type of material.

Choosing the right one is critical. You wouldn’t use a primary crusher to make sand, just as you wouldn’t use a final-stage crusher to break a 3-foot boulder. The “right” machine depends on the material’s hardness, its initial size, and the final product you need to make.

This section is your guide to these five essential machines.

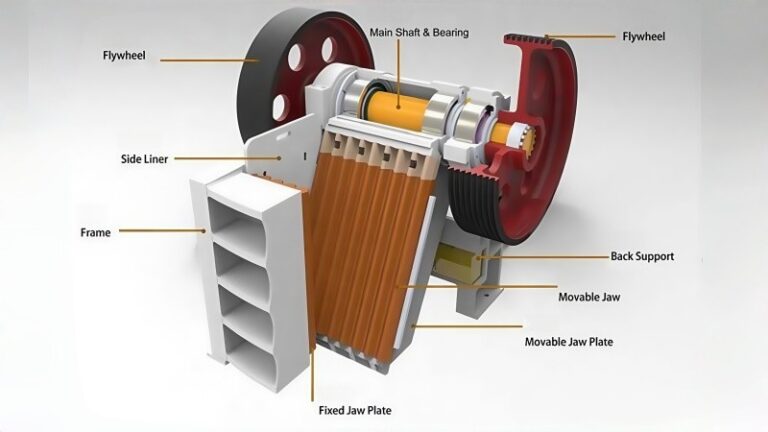

Jaw Crusher – The Versatile Primary Crusher

The jaw crusher is the workhorse of the crushing industry. It’s the most common type of crusher you’ll find, used in quarries, mines, and recycling operations.

- Crushing Principle: It uses the compression principle.

- How it Works: A jaw crusher has two heavy steel plates, or “jaws.” One jaw is fixed (the stationary jaw), while the other (the swing jaw) moves back and forth in a small arc.

- Large rocks are fed into the V-shaped opening at the top.

- The swing jaw moves in and squeezes the rock against the stationary jaw.

- The rock shatters and falls lower into the chamber.

- The jaw opens, letting the material drop further, and then closes again for the next squeeze.

- This process repeats until the pieces are small enough to fall out of the bottom opening.

- Main Role: This is the classic primary crusher. Its job is to take the largest, most difficult rocks—sometimes several feet wide (called “run-of-mine” feed)—and break them down into a more manageable size, like 6 to 10 inches, for the next crushing stage.

Its simple, robust design makes it ideal for handling very hard, abrasive materials (like granite) and even for breaking up large, rebar-filled slabs of recycled concrete.

Gyratory Crusher – The High-Capacity Primary Crusher

If the jaw crusher is the workhorse, the gyratory crusher is the high-capacity giant. It is designed for one purpose: to crush massive volumes of rock continuously.

- Crushing Principle: It also uses compression.

- How it Works: Imagine a massive, upside-down steel cone (the “mantle”) wobbling inside a giant, fixed steel bowl (the “concave”).

- Rock is dumped in from the top, filling the entire chamber.

- The mantle rotates with an eccentric (wobbling) motion.

- This motion continuously squeezes and crushes the rock against the outer concave liners.

- Main Role: This is exclusively a primary crusher for very large-scale operations, such as major mines and the world’s largest quarries. Unlike a jaw crusher that crushes in “bites,” a gyratory crushes continuously, allowing for a much higher throughput. It’s common to see dump trucks pouring hundreds of tons of rock directly into the gyratory’s opening without stopping.

Cone Crusher – For Secondary & Tertiary Crushing

After a primary crusher (like a jaw or gyratory) has done its job, the cone crusher takes over.

- Crushing Principle: Compression, just like a gyratory crusher.

- How it Works: A cone crusher is, in fact, a direct descendant of the gyratory crusher. It has the same wobbling mantle inside a fixed bowl. The key differences are its shape and speed. A cone crusher’s chamber is much flatter and it spins significantly faster.

- Main Role: This is the main machine for secondary and tertiary crushing (the second and third crushing stages).

- It is not designed to break 3-foot boulders.

- It is designed to take the 6-inch rock from the primary crusher and break it down into small, usable aggregate (e.g., 3/4-inch to 1.5-inch).

- Key Feature: Its main job is shaping and sizing. The high speed and crushing action are excellent at breaking rocks in a way that creates a more cubical (square-like) shape. This shape is highly desired because it makes stronger, more durable concrete and asphalt. The output size (known as the “closed-side setting”) is also highly adjustable, though the exact range will depend on the specific model and liners, so it’s always best to check these details with the supplier.

Horizontal Shaft Impact (HSI) Crusher

Now we switch from squeezing to striking. The HSI (Horizontal Shaft Impact) crusher is a powerful machine that uses the impact principle. In everyday industry terms, this is the machine people often mean when they say “Impact Crusher” or simply “an Impactor.”

- Crushing Principle: Impact (high-speed striking).

- How it Works:

- Inside the crushing chamber, a heavy, fast-spinning rotor is mounted with “blow bars” (thick, hardened metal bars).

- Material is fed into the side of this rotor.

- The blow bars strike the rock with tremendous force, shattering it instantly.

- The shattered pieces are then thrown at high velocity against stationary “breaker plates” (heavy metal curtains or walls), causing them to shatter even more.

- Main Role: HSIs are excellent secondary crushers. They are famous for their high reduction ratio, meaning they can take a 10-inch piece of rock and turn it into a 1-inch product in a single pass.

- Best Application: This is very important: HSIs are best for softer, less abrasive materials. They are perfect for limestone, dolomite, gypsum, and recycling concrete and asphalt. Using an HSI on very hard granite would cause the blow bars to wear down extremely fast, making it too expensive to operate.

Vertical Shaft Impact (VSI) Crusher – The Sand Maker

Finally, the VSI is the ultimate shaping tool and is often called the “sand maker.”

- Crushing Principle: Impact, but in a unique way.

- How it Works: Think of a VSI as a high-speed industrial centrifuge.

- Material is dropped into the center of a rapidly spinning rotor.

- The rotor slings the rock outwards at an extremely high velocity (e.g., 150-300 feet per second).

- The rock then smashes against a stationary wall.

The “wall” it hits is what defines the two types of VSI:

- Rock-on-Rock (Autogenous): In this setup, the spinning rock is thrown against a pocket of crushed rock that lines the chamber. The rock breaks against itself. This is the preferred method for making “manufactured sand” and creating the best possible cubical shape, as it minimizes wear on the machine.

- Rock-on-Steel (Anvil): Here, the rock is thrown against a wall of high-strength metal anvils. This provides more crushing energy and is used when a specific product shape is needed from harder materials.

Main Role: This is a tertiary or quaternary (third or fourth stage) crusher. Its only job is to take already-small aggregate (e.g., 1-inch) and either create fine, sand-like particles or perfect the cubical shape of the final aggregate product.

Other Common Crusher Types

Beyond the “big five,” are there other types of crushers?

Yes. Beyond the primary types used for hard rock, more specialized machines like the Hammer Crusher and the Roll Crusher are common. These are typically used for specific applications, such as processing softer, less abrasive materials like coal, limestone, or sticky clays where the main crushers might not be the best fit.

These machines are not usually the first choice for processing extremely hard granite, but they are essential in many other industrial mineral and recycling circuits.

Hammer Crusher

A hammer crusher is a type of impact crusher, but it works differently than an HSI.

Instead of large, fixed blow bars, a hammer crusher uses a high-speed rotor armed with many pivoting “hammers.” Think of it as a chamber full of swinging sledgehammers, all spinning in a circle at high velocity.

How It Works

- Material is fed into the top of the crushing chamber.

- The spinning hammers strike the material with a powerful shattering force.

- The material is also thrown against the chamber walls and breaker plates, causing further reduction.

- The key feature: The bottom of the chamber is lined with a heavy-duty grate or screen. The material is continuously hit inside the chamber until it is small enough to fall through the openings in this grate.

This grate system gives the hammer crusher excellent control over the final product size. By changing the size of the grate openings, an operator can precisely determine the maximum size of the output.

- Best For: Soft to medium-hard, non-abrasive materials. It is a dominant machine in industries like:

- Coal Processing: Breaking coal down to a specific size for power plants.

- Mineral Crushing: Processing limestone, gypsum, and phosphate rock.

- Recycling: In recycling, hammer crushers are effectively used to process brittle materials, such as crushing concrete, bricks, and other demolition waste.

Roll Crusher

A roll crusher is a simple, heavy-duty machine that operates on the pure principle of compression.

It uses one or two large, heavy cylinders (rolls) to break material.

How It Works

- Material is fed into the gap, or “nip,” between two large, heavy rolls that are rotating toward each other.

- The rolls grab the material and pull it down into the gap.

- The material is crushed as it is squeezed by the immense compressive force between the two rolls.

- The crushed product then falls straight out the bottom.

The size of the final product is directly controlled by the distance between the two rolls. This “setting” can often be adjusted.

Roll crushers can have smooth-faced rolls for fine crushing or toothed/corrugated rolls to help grab larger feed material.

- Best For: This type of crusher is often chosen for sticky or wet materials that might clog or “pack” the chamber of a cone or jaw crusher. It’s commonly used for:

- Softer minerals like coal and limestone.

- Industrial materials like bauxite or clays.

- Some specific mining applications where other crushers struggle with the material type.

Crusher vs. Grinder: What is the Difference?

So, aren’t crushers and grinders just the same thing?

No. The main difference is the final product size and the stage in which they are used. A stone crusher is a machine that breaks large rocks into smaller, coarse pieces (like gravel). A grinder, often called a mill, takes those small pieces and pulverizes them into a very fine powder (like sand or flour).

They are two distinct steps in a process called comminution (the an industry term for reducing particle size). You can think of it as a two-part job: crushers do the heavy, “coarse” work, and grinders do the fine, finishing work.

Crushers: Making Big Rocks into Small Rocks

As we’ve discussed in this guide, a crusher’s job is coarse size reduction.

The entire purpose of a crusher (like a Jaw, Cone, or HSI) is to take a large, unusable feed material and break it down into smaller, solid particles.

- Input: Large boulders or rocks, often measured in feet or large inches (e.g., 24-inch rocks).

- Output: Smaller, solid particles, measured in inches (e.g., 3/4-inch to 2-inch aggregate).

- The Goal: The final product is still a distinct “rock.” You can pick up a single piece. The goal is either to create a specific size of aggregate for construction or to “liberate” valuable ore from waste rock for the next stage.

In a mining operation, a primary jaw crusher breaks the large, ore-bearing rock. This doesn’t get the gold out, but it makes the rock small enough for a conveyor belt to handle and feed into the next machine.

Grinders (Mills): Making Small Particles into Powder

A grinder, known in the industry as a mill, performs the next and final stage of size reduction. Its job is to take the small rocks from a crusher and turn them into a fine, uniform powder.

- Input: Small, crushed particles, usually under 1 inch in size (the output from a cone crusher, for example).

- Output: A fine powder or slurry, measured not in inches but in mesh size or microns (e.g., 200-mesh, which is as fine as flour).

- The Goal: The final product is no longer a “rock”—it’s a powder. This is done to:

- Create products like cement or agricultural lime.

- Fully liberate microscopic mineral particles (like gold or copper) from the waste rock so they can be separated using chemical processes (like flotation).

How Grinders (Mills) Work

They use different principles than most crushers. Instead of a single squeeze or strike, they use continuous attrition (rubbing) and abrasion.

The most common types are Ball Mills or Rod Mills. A ball mill is a large, rotating drum filled with hard steel balls. The crushed rock is fed into the drum, and as it tumbles, the steel balls cascade and grind the rock against itself and the liner, pulverizing it into a fine powder.

Here is a simple breakdown of the key differences:

| Feature | Stone Crusher | Grinder (Mill) |

|---|---|---|

| Primary Job | Coarse reduction | Fine/Ultrafine reduction |

| Feed Size | Very large (e.t., 24+ inches) | Small (e.g., < 1 inch) |

| Product Size | Small rocks / Gravel (measured in inches) | Fine powder / Slurry (measured in mesh/microns) |

| Main Principle | Compression or Impact | Attrition (rubbing) and Abrasion |

| Common Types | Jaw, Cone, Gyratory, HSI, VSI | Ball Mill, Rod Mill, SAG Mill |

| Industry Goal | Create aggregate; prepare feed for mills | Create cement; liberate minerals for processing |

What is a Stone Crusher Plant?

So, does a quarry just use one single, giant crusher?

No. A stone crusher plant (or crushing station) is not a single machine but a complete, interconnected system. It is an engineered arrangement of multiple crushers, screens, and conveyors designed to take large rocks and efficiently process them into specific, graded final products in a continuous operation.

Instead of one machine doing all the work, a plant uses different machines for different stages of size reduction. This entire system is often called a “crushing circuit.”

Think of it like a multi-stage machining process. You wouldn’t use a heavy-duty roughing tool to create a final, polished surface. In the same way, a plant uses a series of crushers to get the job done efficiently:

- Primary Crushing: The first, heavy-duty stage. It uses a Jaw or Gyratory crusher to break the largest boulders (“run-of-mine” rock) into a more manageable size (e.g., 6-8 inches).

- Secondary Crushing: This stage takes the 6-inch rock from the primary crusher and reduces it further, typically using a Cone Crusher or an HSI.

- Tertiary (or Quaternary) Crushing: The final stage. This stage uses a Cone Crusher or a VSI to shape the rock into its final cubical form and to produce manufactured sand.

These plants can be massive, stationary structures fixed in concrete at a quarry, or they can be mobile crusher plants built on tracks or trailers for easy movement between construction or recycling sites.

The Main Components of a Crushing Circuit

While every plant is unique, most are built from the same four main types of components. The exact layout and which specific models are used can vary significantly based on the rock type and the operator’s goals, so these details are always customized with the supplier.

1. Feeders (The Starting Point)

The circuit begins with a feeder. You cannot simply dump 50 tons of rock directly into a crusher; it would “choke” the machine. A feeder, like a vibrating grizzly feeder, controls the flow.

- What it does: It takes the large, unsorted rock from a dump truck or excavator and feeds it to the primary crusher at a steady, controlled rate.

- Why it’s important: Many grizzly feeders have a built-in “grizzly” section, which is a set of heavy steel bars. This acts as a pre-screen. Any dirt and rock that is already small enough simply falls through the bars and bypasses the crusher. This is a huge efficiency gain—it saves energy and prevents unnecessary wear on the primary crusher.

2. Crushers (The Muscle)

This is the heart of the plant, using the machines we’ve already discussed (Jaw, Cone, HSI, VSI). A plant will have several, each set for a specific job—one for primary breaking, one for secondary reduction, and one for final shaping and sand making.

3. Vibrating Screens (The Sorter)

The vibrating screen is arguably the most important component for creating a quality product. It acts as the “director” of the entire circuit.

- What it does: A screen is a large, vibrating box with multiple layers (or “decks”) of screen mesh. As material vibrates across it:

- The largest rocks stay on the top deck.

- Medium rocks fall through to the second deck.

- The smallest, finished product falls through all the decks to the bottom.

- Why it’s important: The screen is what “closes the circuit.”

- Material that is the correct size (e.g., 3/4 inch) is sent to a product stockpile.

- Material that is still too big is sent on a conveyor belt back to the same crusher it just came from for another pass. This is called a “closed-circuit” operation. This loop is the only way to guarantee that every single rock in the final product pile is the correct specification.

4. Conveyors and Stockpiles (The Finish Line)

Conveyors are the material transport network of the plant. These belts move thousands of tons of material per hour between each machine: from the feeder to the crusher, from the crusher to the screen, from the screen back to the crusher, and finally, from the screen to the finished product piles, known as stockpiles.

The stockpiles are where the final, separated products (e.g., 1-inch stone, 3/4-inch stone, and manufactured sand) are stored, ready for sale.

What Do Stone Crushers Produce? (The Final Products)

So, after all that crushing, what are the actual products sold?

Stone crushers produce three main categories of materials: specification aggregates (graded crushed stone), manufactured sand (M-sand), and crusher dust (or fines). These products are the primary ingredients for concrete, asphalt, and road base materials.

The entire purpose of a stone crusher plant is not just to make rocks smaller, but to sort those smaller pieces into very specific size ranges. Different jobs require different sizes, and the value of the final product is determined by how well it has been crushed and sorted.

Aggregates (Crushed Stone)

This is the main, high-value product. “Aggregates” is the industry term for the gravel and crushed stone used in construction.

After crushing, these rocks are sorted by vibrating screens into different stockpiles. Each pile is a “graded” product, meaning it contains rocks of a consistent size.

These products are valued for two key things:

- Size: The size is uniform, as specified by the customer.

- Shape: The rock has been broken, not just worn down by a river. This means it is angular and cubical (square-like), which is a shape that interlocks like blocks. This interlocking is what gives concrete and asphalt their strength.

Common uses for aggregates depend entirely on their size:

- Large Aggregates (e.g., 2-3 inches): Used as a heavy-duty, stable foundation for roads (called a sub-base) or for large drainage and erosion control projects (called “rip-rap”).

- Medium Aggregates (e.g., 3/4-inch to 1.5-inch): This is the most common and valuable product. This is the primary ingredient mixed with cement to make concrete and with bitumen to make asphalt for roads.

- Small Aggregates (e.g., 3/8-inch): Often called “pea gravel,” this is used for specialized concrete mixes, walkways, and drainage.

While standard sizes (like #57 stone in the US) are common, the exact specifications can vary significantly by region and project. Operators will adjust their plant’s crushers and screens to meet a customer’s specific needs.

Manufactured Sand

This is one of the most important and fastest-growing products from a crusher plant. Manufactured sand (or M-sand) is exactly what it sounds like: a “man-made” sand created by a crusher.

It is not natural sand dug from a riverbed or beach. It is made on purpose, typically by a VSI (Vertical Shaft Impactor) crusher. The VSI is set to pulverize small aggregates, breaking them down into sand-sized particles.

Why is this so important?

- Sustainability: Natural sand is a limited resource. Rivers and coastlines are being damaged by over-mining. M-sand is a 100% sustainable alternative made from a plentiful rock source.

- Superior Quality: Unlike rounded, smooth river sand, M-sand has the same angular, cubical shape as aggregates. This shape provides a better “interlock” in concrete, often resulting in a stronger, more durable final product.

- Consistency: The quality of natural sand can vary wildly. M-sand is an engineered product with perfect consistency, free of silt, clay, or organic junk.

It is used as a high-performance, direct replacement for natural sand in all concrete and asphalt production.

Crusher Dust / Fines

This is the finest material produced, the “leftover” powder from the crushing process. It consists of any particle that falls through the very smallest screen (e.g., anything smaller than 3/16 inch or 5mm).

This material was once considered a low-value waste product, but today it is a valuable part of the process. These “fines” have two main uses:

- Asphalt and Concrete Filler: A certain amount of fine powder is needed in asphalt and concrete mixes to fill the microscopic gaps between the sand particles. Crusher dust acts as this essential “mineral filler.”

- Compacted Road Base: This is its most common use. Fines are blended back in with larger aggregates to create a product called “crusher run” or “road base.” The larger stones provide the strength, and the fines act like mortar, filling all the tiny gaps. When this mix is watered and compacted, it creates an incredibly dense, stable, and water-resistant foundation for roads and buildings.

Conclusion

From the massive primary jaw crusher to the precision of a VSI sand maker, the stone crusher is a foundational machine. It’s not just one tool, but a complete system—a crusher plant—that transforms raw, unusable rock into the essential aggregates, sand, and fines that build our roads, cities, and infrastructure. Understanding the different types, principles, and plant components is key to seeing how our modern world is built from the ground up.