how does an impact crusher actually break down massive rocks?

An impact crusher works by using high-speed, powerful strikes to break material instead of compression. It features a spinning rotor that strikes the feed material, shattering it and throwing it against stationary impact plates for further reduction.

The term “impact crusher” actually covers two main types: the Horizontal Shaft Impactor (HSI) and the Vertical Shaft Impactor (VSI). Because the HSI is the model most people mean when they say “impact crusher,” this article will primarily use it to explain the common applications, pros, cons, and components. We will then contrast it with the specialized VSI.

What is an Impact Crusher?

An impact crusher is a heavy-duty machine designed to reduce the size of large rocks, concrete, and ores using kinetic energy. Unlike jaw or cone crushers, which use compression (squeezing force) to break material, an impact crusher uses intense, rapid striking forces—similar to shattering a rock with a giant sledgehammer.

These machines are typically used as secondary or tertiary crushers in aggregate production and recycling plants. They are prized for their ability to produce a uniform, cubical product shape and a high reduction ratio, making them essential for processing materials that are not excessively abrasive or hard.

What Can an Impact Crusher Be Used For?

So, where do these machines actually fit into a worksite, and what are they crushing?

Impact crushers are vital in aggregate production, construction and demolition (C&D) recycling, and some mining operations. Their primary use (referring to the common HSI) is breaking down materials of low to medium hardness, such as limestone, concrete, and asphalt.

Primary Applications: Aggregate, Recycling, and Mining

An impact crusher is a versatile machine found in three main industries.

- Aggregate Production: This is the most common use. Quarries use impact crushers as a secondary or tertiary (third-stage) crusher. After a large jaw crusher does the initial breaking, the impactor takes the mid-sized rock and shatters it into smaller, specific sizes (like gravel and sand) needed for road base, concrete mix, and construction fill.

- Recycling: This is a rapidly growing field. Impact crushers are excellent at processing construction and demolition (C&D) waste. They take large, irregular chunks of old concrete and asphalt and break them down into a reusable product, often called “recycled aggregate.”

- Mining: In mining, impactors are used in softer-rock applications. They are effective for ores like softer iron ore, phosphate, and gypsum.

Ideal Materials: Processing Concrete, Asphalt, and Limestone

Impact crushers (specifically HSIs) work best when the material is brittle—meaning it shatters easily on impact.

- Limestone: This is the classic material for an impact crusher. Limestone is a softer rock that shatters perfectly when struck by the blow bars, making it ideal for creating base material for roads and foundations.

- Asphalt (RAP): Recycled Asphalt Pavement (RAP) is also brittle. The impactor’s high-energy blows cleanly break the pavement apart. This action frees the valuable bitumen (the black “glue”) and aggregate to be reused in new hot-mix asphalt.

- Concrete: Impact crushers are the top choice for recycling concrete for a specific reason: rebar.

Recycling: The Impact Advantage

When recycling concrete, the goal isn’t just to make small rocks; it’s to “liberate” or free the steel rebar from the concrete.

Industry Analogy: Think of a jaw or cone crusher, which uses squeezing pressure. It might simply bend a piece of rebar and jam the machine. An impact crusher, however, acts like a powerful hammer. Its forceful strike shatters the concrete off the rebar, allowing downstream magnets to easily pick the clean steel out of the material pile.

Unsuitable Materials: When to Avoid Using an Impact Crusher

An impact crusher is a powerful tool, but it is not the right choice for every job. Using it on the wrong material can be a very expensive mistake.

The primary enemies of the common impact crusher (the HSI) are highly abrasive and extremely hard materials.

- Examples: This includes materials like hard granite, quartzite, basalt, and most hard river rock.

- The Problem: These rocks often contain a high percentage of silica. Silica is an extremely hard mineral that acts like sandpaper.

- The Consequence: Because the impact crusher works by direct high-speed striking, these abrasive rocks will rapidly wear down the machine’s primary wear parts—the blow bars.

Industry Analogy: Using a standard impact crusher on high-silica granite is like trying to shape a tough grinding wheel with a simple steel hammer. The “hammer” (your blow bars) will be worn down to a rounded, useless shape in a very short amount of time by the “grinding wheel” (the abrasive rock).

What’s the result? The operator will suffer from constant downtime for maintenance and extremely high costs for replacing the wear parts. This core limitation is precisely why the other type of impact crusher, the VSI, was developed.

How Do the Different Types of Impact Crushers Work?

Do all impact crushers use the same design to break rock?

Yes, impact crushers are split into two main types based on the orientation of their rotating shaft: the Horizontal Shaft Impactor (HSI) and the Vertical Shaft Impactor (VSI). While both use high-speed impact, their mechanisms and applications are very different.

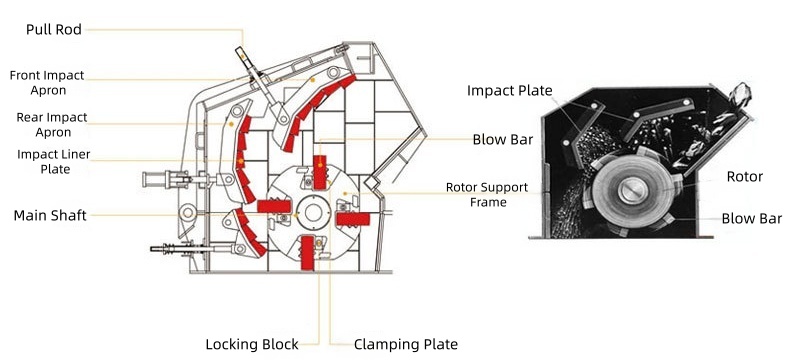

The HSI (Horizontal Shaft Impactor): Principle and Mechanism

The Horizontal Shaft Impactor (HSI) is the design most commonly referred to as a “standard” impact crusher. It’s often used in secondary crushing and recycling. Its mechanism is a powerful, multi-stage process.

- Feeding and First Impact: Material (like limestone or concrete) is fed into the top of the crushing chamber. It immediately meets a heavy, horizontal rotor. This rotor has several “blow bars” (hammers) mounted on it, spinning at a high speed. The blow bars strike the material, shattering it in mid-air. This is the first and most powerful impact.

- Second and Third Impacts: The force of this blow throws the shattered pieces at high velocity against stationary “impact plates” (also called aprons) that line the upper part of the chamber. When the rock hits these plates, it shatters again.

- Final Reduction: The material then rebounds from the plates and often falls back into the path of the spinning blow bars for another impact. This cycle repeats until the particles are small enough to pass through the discharge opening at the bottom of the crusher.

Industry Analogy: Think of an HSI as a powerful, enclosed sledgehammer machine. The rotor with its blow bars is like a spinning wheel of sledgehammers. It repeatedly strikes the rock and throws it against a solid steel anvil (the impact plates) until it’s broken down.

The final product size is controlled by two main factors: the speed of the rotor (measured in RPMs) and the distance, or gap, set between the blow bars and the impact plates. This gap can often be adjusted hydraulically. Because these settings can differ based on the material’s properties, you should always consult the manufacturer’s guide for the correct gap and speed recommendations.

The VSI (Vertical Shaft Impactor): Rock-on-Rock vs. Rock-on-Anvil

The Vertical Shaft Impactor (VSI) works on a completely different principle. It uses centrifugal force to break material, which is why it’s sometimes called a ‘centrifugal crusher’ or, in many applications, a ‘Sand Making Machine’.

VSIs are specifically used to process the hard, abrasive materials (like granite and quartzite) that HSIs cannot efficiently handle.

Instead of hammers, a VSI has a high-speed vertical rotor in the center. Material is fed into the center of this rotor. The rotor spins extremely fast (e.g., 50 to 75 meters per second), accelerating the material and slinging it outward into a stationary crushing chamber.

What the material hits in that chamber defines the two types of VSI crushing:

Rock-on-Rock (Autogenous) Crushing

In this setup, the outer chamber is designed to create a “shelf” of compacted material (the same rock that is being crushed). The high-velocity particles slung from the rotor then smash into this stationary bed of rock.

- Mechanism: This is an “autogenous” process, meaning the material breaks itself. This is ideal for abrasive materials because the abrasive rock wears against itself, not expensive metal parts.

- Industry Analogy: Imagine a high-speed stacking conveyor slinging material. Now, enclose that in a circular chamber where the material it slings hits a wall built from the material that has already been slung. The high-velocity impact of stone-on-stone does the breaking.

- Result: This method is less about breaking down large pieces (reduction) and more about shaping the particles. It effectively chips off sharp edges, creating a more uniform, cubical product. This is why VSIs are often called “shapers.”

Rock-on-Anvil Crushing

In this configuration, the outer chamber is lined with hard, stationary anvils made of high-chrome iron or other durable composites.

- Mechanism: The high-velocity particles are slung from the rotor and smash directly against these metal anvils.

- Result: This creates a much higher impact force and is used when more size reduction is needed. It is a more aggressive form of crushing than rock-on-rock.

HSI vs. VSI: Key Differences in Function and Output

While both are “impactors,” HSIs and VSIs are not interchangeable. They are used at different stages of crushing and for different goals.

| Feature | HSI (Horizontal Shaft Impactor) | VSI (Vertical Shaft Impactor) |

|---|---|---|

| Working Principle | Direct “sledgehammer” strikes from blow bars. | Centrifugal force slings material outward. |

| Typical Feed Size | Can accept larger feed (e.g., up to 14 in / 350mm). | Must have smaller, pre-crushed feed (e.g., < 2 in / 50mm). |

| Crushing Stage | Typically Secondary or Tertiary. | Typically Tertiary (3rd) or Quaternary (4th stage). |

| Primary Goal | High reduction ratio; breaking down material. | Shaping product; creating fine aggregate (manufactured sand). |

| Common Use | Aggregate, concrete/asphalt recycling. | Final shaping, sand manufacturing, crushing hard/abrasive rock. |

What Are the Pros and Cons of Using an Impact Crusher?

So, why would an operator choose an impact crusher, and what are the downsides?

The main advantages of an impact crusher are its ability to produce a superior, cubical-shaped product and its high reduction ratio. However, its primary disadvantage (specifically for the HSI model) is the high operating cost due to rapid wear when processing hard or abrasive materials.

The Key Advantage: Superior, Cubic-Shaped Product

This is the most important benefit of an impact crusher. In the aggregate industry, shape sells.

An impact crusher (both HSI and VSI) works by shattering rock, which tends to break the material along its natural cleavage lines. This process creates particles that are roughly equal in length, width, and height—like a small cube.

Why is this “cubical” shape so important?

- Contrast with Other Crushers: Compression crushers (like jaw or cone crushers) “squeeze” the rock. This squeezing action can often create thin, flat, or elongated particles, which are known as “flaky” or “slabby.”

- Better Concrete: When mixing concrete, flaky particles leave more voids (empty spaces) that must be filled with expensive cement and water. Cubical particles interlock tightly, creating a stronger, denser concrete mix with less cement paste.

- Stronger Asphalt: For asphalt roads, cubical aggregate provides better stone-on-stone contact. This creates a more stable pavement that is highly resistant to rutting (the grooves worn into the road by tires).

Industry Analogy: Using flaky aggregate in concrete is like trying to build a solid wall with thin, flat wood chips. Using cubical aggregate is like building with uniform bricks. The “brick” wall is stronger, more stable, and requires less mortar to hold it together.

Other Benefits: High Reduction Ratio and Efficiency

Beyond product shape, impact crushers (specifically HSIs) offer two other major advantages:

- High Reduction Ratio: “Reduction ratio” refers to how much smaller the crusher can make the material in a single pass. Because the material is struck multiple times (by the blow bars, then the impact plates), an HSI can have a very high reduction ratio, sometimes as high as 15:1. This means it can take a 15-inch piece of rock and turn it into a 1-inch product. This high ratio can sometimes eliminate the need for an entire crushing stage, simplifying the plant and saving money.

- High Throughput: The design of the crushing chamber allows a large volume of material (high tonnage) to flow through the machine quickly without choking. This makes it very efficient for processing softer materials and recycled products at a high rate.

The Main Disadvantage: High Wear Costs on Abrasive Materials

The greatest strength of the HSI-style impact crusher is also its greatest weakness. The same high-speed striking that creates a great product shape also causes intense wear on the machine’s internal components.

- Sacrificial Parts: The blow bars and impact plates are “sacrificial” parts. They are designed to be worn away and replaced.

- The Problem: When crushing materials that are hard or abrasive (containing high levels of silica, like granite or quartzite), this wear happens extremely fast.

- The Cost: This isn’t just the cost of buying new parts.

- Downtime: The entire plant must be shut down for maintenance, which can cost thousands of dollars per hour in lost production.

- Labor: It requires skilled labor to safely replace heavy components inside the crusher.

For example, a set of blow bars might last 250 hours when crushing soft limestone. That same set of bars might only last 60 hours when crushing abrasive recycled concrete, dramatically increasing the cost-per-ton of the final product.

The exact lifespan of your wear parts will always depend on the rotor speed, the feed rate, and the specific abrasiveness of your material. It is critical to discuss these factors with your equipment supplier to estimate your true operating costs.

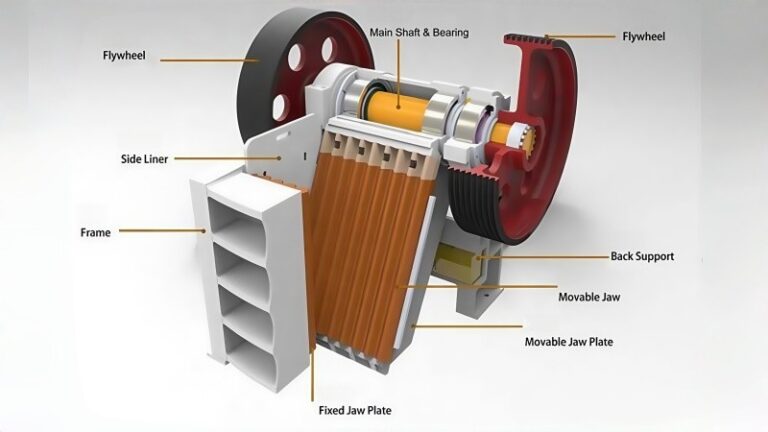

What Are the Key Components That Make It Work?

So, what are the main parts inside an impact crusher that actually break the rock?

The key components that make the common (HSI) impact crusher work are the rotor and its mounted blow bars, the stationary impact plates or aprons, and the drive system. The drive spins the rotor at high speed, allowing the blow bars to strike the material and throw it against the impact plates.

Let’s look at each of these parts to see how they function together.

The Rotor and Blow Bars (The Striking Force)

This assembly is the heart of the HSI.

- The Rotor: This is a heavy, solid steel drum or “spool” that spins at high velocity. Its job is to store and transfer immense kinetic energy (energy of motion) into the material being crushed.

- The Blow Bars: These are the “hammers” of the machine. They are heavy, replaceable bars made of highly durable materials, typically high-chrome iron or specialized composites. They are mounted directly onto the rotor.

When the drive system spins the rotor, the blow bars strike the incoming rock with massive, sudden force. This is the primary impact that does most of the initial breaking.

Industry Analogy: The rotor and blow bars act like the milling drum on a road planer (or cold planer). The rotor is the spinning drum, and the blow bars are the cutting teeth, which aggressively strike the material (the pavement) to break it apart.

Because they take the brunt of every impact, blow bars are designed as sacrificial wear parts. They must be regularly inspected, rotated, and eventually replaced to maintain the crusher’s performance.

The Impact Plates / Aprons (The Rebound and Sizing Surface)

If the blow bars are the “hammer,” the impact plates are the “anvil.” These are the heavy, stationary liners, also made of wear-resistant metal, that form the upper “ceiling” of the crushing chamber.

They serve two critical functions:

- Rebound Surface: When the blow bars strike the rock, it explodes and is thrown at high speed against these impact plates. This creates a secondary, and just as important, crushing action.

- Sizing and Adjustment: These plates are almost always adjustable. The distance between the spinning blow bars and these stationary plates is called the “gap.” This gap is the primary control for the final product size.

How Adjustment Controls Product Size

- A Wider Gap: Setting a wider gap allows material to exit the chamber more easily. This results in a larger, coarser final product and higher throughput (more tons per hour).

- A Tighter Gap: Closing the gap forces the material to stay in the crushing chamber longer. It will be struck by the blow bars and rebound off the plates multiple times before it is small enough to exit. This creates a much finer, smaller final product.

The Crushing Chamber and Drive System

These components support and power the entire operation.

- The Crushing Chamber: This is the heavy-duty steel housing that encloses the rotor and impact plates. It is designed to contain the violent impacts, safely funnel material from the feed opening at the top, and allow the final product to fall out of the discharge opening at the bottom.

- The Drive System: This is the “engine” that makes the crusher work. In stationary plants, this is typically a large electric motor. On mobile, track-mounted crushers, it is usually a powerful diesel engine.

This power is transferred from the motor to the rotor using a system of heavy-duty V-bels and sheaves (pulleys). The amount of power required (measured in horsepower or kilowatts) is significant and determines the crusher’s capacity. The specific power requirements can vary based on the crusher’s size and the hardness of the material being processed, so it’s always best to confirm these details with your equipment supplier.

Conclusion

In summary, an impact crusher is a powerful tool that relies on high-speed strikes rather than compression. As we’ve seen, this term most often refers to the HSI (Horizontal Shaft Impactor), which excels at high-reduction ratios and creating cubical aggregate from less-abrasive materials.

Understanding the differences between an HSI and a VSI (Vertical Shaft Impactor, or Sand Maker)—which excels at handling the very abrasive rock that HSIs cannot—is critical. By matching the right crusher type to the right material, operators can maximize efficiency, control wear costs, and produce a valuable end-product.