Product Introduction

The PC Box-Type Crusher (also known as a Box Hammer Crusher) is mainly used for the primary and secondary crushing of materials with a compressive strength of less than 300MPa and medium hardness. It is widely used in mining, building materials, chemicals, and metallurgy industries.

After optimizing the structural design, this machine utilizes a heavy-duty rotor and hammer system to achieve a major breakthrough in crushing technology. It effectively combines the crushing stages, achieving a “multiplier effect.” With a large feed inlet and high crushing ratio, it produces a uniform output where granular products account for about 85%, fully meeting high-quality aggregate requirements.

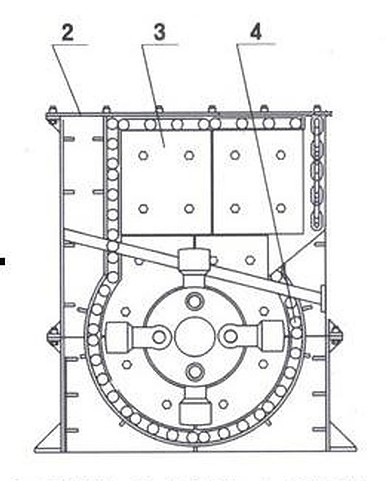

Working Principle

The core of the Box Crusher is a massive rotor equipped with heavy-duty hammers. The motor drives the rotor to rotate at high speed. Materials are fed into the crushing chamber and are impacted by the hammers.

The stone is shattered and thrown against the impact liners inside the “box” housing. The grid/grate bars at the bottom control the output size—material stays in the chamber until it is crushed small enough to pass through the grate gaps. This design ensures accurate sizing and high efficiency.

Overview of Advantages

- Large Feeding Size:

Capable of accepting large stones (up to 1600mm), allowing it to function as a primary crusher, reducing the need for a jaw crusher in some lines. - Extended Hammer Life (30,000-40,000 Tons):

By optimizing the design and reducing hammer wear in the crushing chamber, the service life of the hammer heads is increased by 4-6 times compared to standard crushers, significantly reducing maintenance costs. - High Quality Output:

The crushing action produces excellent particle shape, with approximately 85% of the output being uniform, granular product (cubic shape). - Energy Efficient:

Designed with small supporting power requirements and low energy consumption, offering high yield for lower operational costs. - Easy Maintenance:

The box-type structure allows for easy access to internal parts, making maintenance simple and fast.

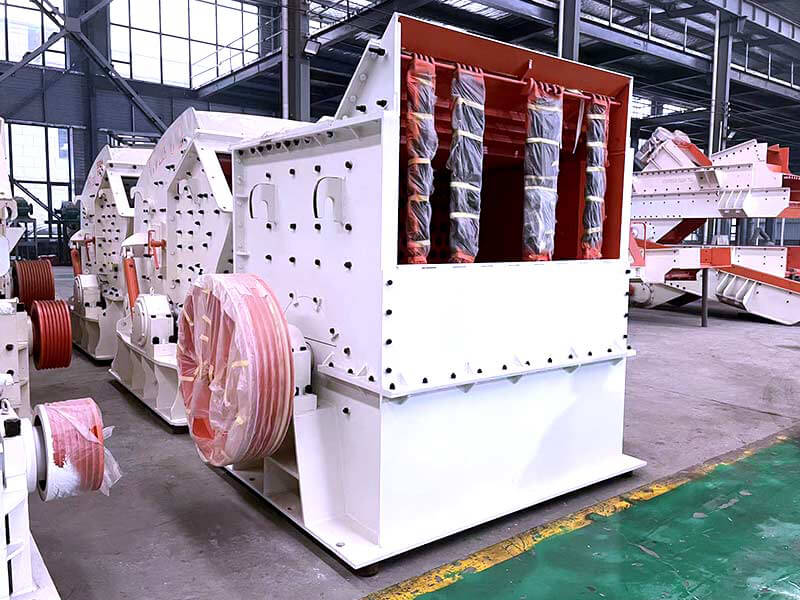

Product Photos

Technical Parameters

| Model | Rotor Diameter (mm) | Rotor Length (mm) | Feeding Size (mm) | Material Strength | Capacity (t/h) | Power (kw) |

|---|---|---|---|---|---|---|

| 600 × 600 | 600 | 600 | ≤400 | ≤ 300MPa (Various types of stone) | 30-60 | 45-55 |

| 800 × 800 | 800 | 800 | ≤500 | 40-80 | 55-75 | |

| 1000 × 1000 | 1000 | 1000 | ≤700 | 50-90 | 75-90 | |

| 1000 × 1200 | 1000 | 1200 | ≤750 | 60-100 | 90-110 | |

| 1200 × 1200 | 1200 | 1200 | ≤900 | 80-120 | 110-132 | |

| 1200 × 1400 | 1200 | 1400 | ≤1000 | 90-150 | 132-160 | |

| 1400 × 1400 | 1400 | 1400 | ≤1100 | 130-200 | 185-220 | |

| 1400 × 1600 | 1400 | 1600 | ≤1200 | 160-280 | 200-250 | |

| 1600 × 1600 | 1600 | 1600 | ≤1400 | 230-300 | 250-315 | |

| 1800 × 1800 | 1800 | 1800 | ≤1600 | 260-400 | 250-320 |