Product Introduction

The Compound Cone Crusher is a modern, high-performance crusher that improves upon the classic spring cone crusher design. It integrates an optimized cavity shape with advanced hydraulic technology, creating a “compound” machine that is both reliable and efficient.

This crusher is based on the lamination crushing principle, where material is crushed between other particles, resulting in a superior cubical product shape with “more crushing and less grinding.” This design combines the rock-solid spring-based overload protection system with the convenience of a hydraulic system for clearing the chamber and adjusting the discharge setting.

It is widely used in metallurgy, construction, road building, mining, and more, and is ideal for the secondary or tertiary crushing of hard and medium-hard materials like iron ore, pebbles, granite, basalt, and quartzite.

Overview of Advantages

- Spring Protection & Hydraulic Locking

This machine retains the reliable spring overload protection system, which allows uncrushable materials (like tramp iron) to pass without damaging the machine. This is combined with a hydraulic locking system (instead of manual locking) for stable and efficient operation. - Hydraulic Adjustment & Clearing

The hydraulic system allows the discharge port (CSS) to be adjusted quickly and easily to meet specific output granularity requirements. It is also used for hydraulic chamber clearing, which saves time and labor during fault maintenance. - High Automation & Excellent Particle Shape

Utilizes a high degree of automation and a long crushing arm for a large crushing ratio and high production. Its lamination crushing principle ensures the final product is cubical in shape with fewer needle-like particles, no internal cracks, and high compressive strength. - Easy to Maintain & Low Wear

The equipment is easy to maintain and service. We utilize new, high-strength, wear-resistant materials for our wearing parts (mantle and bowl liner), resulting in low wear and a long service life. - Proven, Reliable Design

The utility model is constantly being developed and extended, which ensures the equipment has a long service life and is easy to maintain, add, and replace.

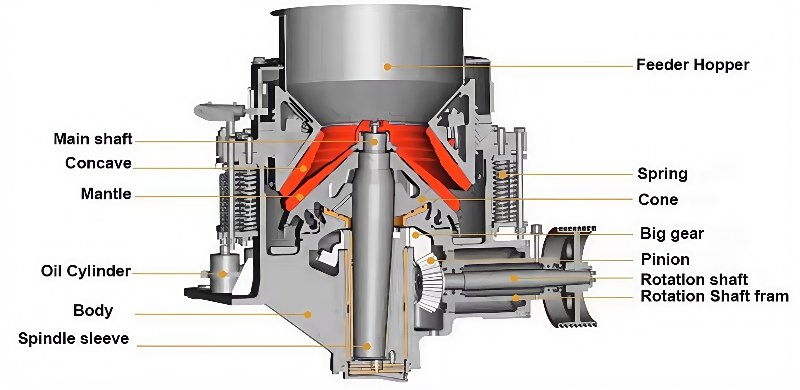

Key Structural Components

As this diagram illustrates, the Compound Cone Crusher’s design combines robust, proven components with modern hydraulics.

- Crushing Chamber: Formed by the inner Mantle (on the movable cone) and the outer Concave (fixed liner), this is where lamination crushing occurs.

- “Compound” System: The design’s core is visible:

- Spring System: The heavy-duty Springs provide reliable overload protection against tramp iron.

- Hydraulic System: The Oil Cylinder allows for quick and easy hydraulic adjustment of the discharge setting (CSS) and simplifies chamber clearing.

- Drive Assembly: A powerful motor drives the Pinion and Big Gear, which rotates the eccentric assembly to create the crushing motion.

- Core Structure: The entire assembly is held by a heavy-duty Main Shaft, Body (Frame), and Spindle Sleeve, ensuring stability and long service life.

Working Principle

The Compound Cone Crusher operates on the classic principle of cone crushers but with enhanced “compound” functionality. The electric motor drives the eccentric shaft through a V-belt and pulley system, causing the movable cone to perform a gyratory motion within the fixed cone. Material fed into the top of the crushing chamber is progressively crushed between the mantle and bowl liner.

Crucially, this machine emphasizes lamination crushing, where material is crushed against itself, resulting in a superior, cubical product shape. The spring system provides reliable protection against tramp iron or uncrushable materials by allowing the crushing cone to yield, preventing damage to the machine. Concurrently, the hydraulic system facilitates precise adjustment of the discharge opening (CSS) and rapid clearing of the crushing chamber, combining robust overload protection with operational flexibility and ease of maintenance.

Product Photos

Technical Parameters

| Model | Movable Cone Diameter (mm) | Cavity Type | Feeding Size(mm) | Discharging Opening Size(mm) | Main Shaft Speed(r/min) | Motor Power(kw) | Capacity (t/h) | Overall Dimension(mm) | |

|---|---|---|---|---|---|---|---|---|---|

| Shuttering Size(mm) | Open Side Size(mm) | ||||||||

| CS75 | 910 | Fine | 83 | 102 | 9-22 | 580 | 75 | 45-91 | 2821 × 1880 × 2164 |

| Coarse | 159 | 175 | 13-38 | 59-163 | |||||

| CS110 | 1200 | Fine | 127 | 131 | 9-31 | 485 | 110 | 63-188 | 2821 × 1974 × 2651 |

| Medium | 156 | 156 | 13-38 | 100-200 | |||||

| Coarse | 178 | 191 | 19-51 | 141-308 | |||||

| CS160 | 1295 | Fine | 109 | 137 | 13-31 | 485 | 160 | 109-181 | 2800 × 2342 × 2668 |

| Medium | 188 | 210 | 16-38 | 132-253 | |||||

| Coarse | 216 | 241 | 19-51 | 172-349 | |||||

| CS220 | 1395 | Fine | 155 | 173 | 19-45 | 485 | 220 | 180-285 | 3360 × 2650 × 3050 |

| Medium | 188 | 198 | 22-50 | 215-330 | |||||

| Coarse | 230 | 245 | 25-65 | 230-570 | |||||

| CS250 | 1650 | Fine | 188 | 209 | 16-38 | 485 | 250 | 181-327 | 3911 × 2870 × 3771 |

| Medium | 213 | 241 | 22-51 | 220-417 | |||||

| Coarse | 241 | 268 | 25-64 | 299-635 | |||||

| CS315 | 2134 | Fine | 253 | 278 | 19-38 | 435 | 315 | 281-726 | 4631 × 3251 × 4732 |

| Medium | 303 | 334 | 25-51 | 608-998 | |||||

| Coarse | 334 | 369 | 31-64 | 789-1270 | |||||