Product Introduction

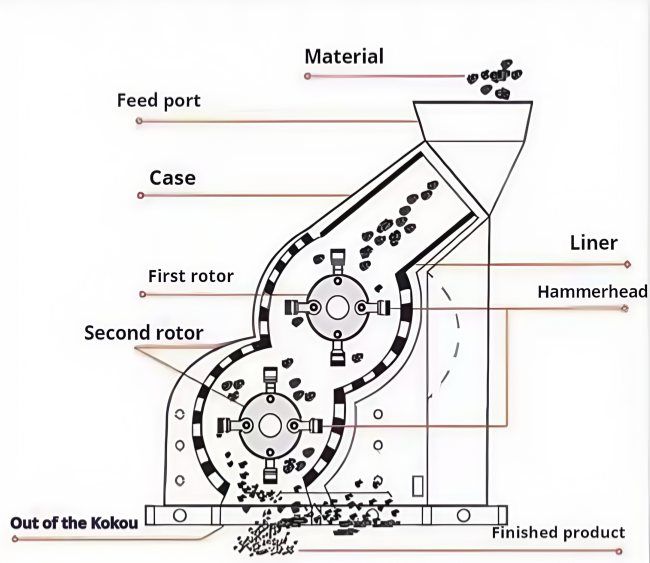

The Double Stage Crusher, technically known as a Twin-Rotor Hammer Crusher, is a specialized industrial crushing machine designed to solve the problem of crushing high-humidity and high-viscosity materials.

Unlike traditional crushers equipped with grate bars, this machine features a screenless design. It utilizes two rotors connected in series (one above the other) to crush materials twice in a single pass. It is the ideal equipment for crushing coal gangue, shale, slag, cinder, and construction waste in the brick and tile, stone, and mining industries. It is specifically engineered to handle materials with moisture content up to 20% without clogging.

Working Principle

- Two-Stage Crushing: The machine has two rotors arranged vertically. Material enters the upper chamber and is initially crushed by the first rotor. It then immediately falls to the second, lower rotor for fine crushing.

- Impact & Collision: The material is not only hit by the hammers but also collides with other particles in the chamber (“stone hitting stone”), achieving a powdering effect.

- Screenless Discharge: There is no screen grate at the bottom. This ensures that wet, sticky, or muddy materials can pass through freely without adhering to or blocking the machine, which is a common failure in standard hammer mills.

Overview of Advantages

- No Screen, No Clogging:

The bottomless design completely eliminates the problem of wet material blocking the sieve plate. It works perfectly even on rainy days or with sticky feedstock. - Twin-Rotor Technology:

Two sets of rotors connected in series enable “hammer crushing hammer” action. The material is crushed repeatedly, resulting in a very fine and uniform output size (typically ≤3mm accounts for over 80%). - High Efficiency for Wet Material:

It is capable of processing materials with moisture content usually below 20% (and even higher depending on viscosity) without compromising efficiency. - Durable Hammer Heads:

The hammers are made of high-alloy wear-resistant materials. Their position can be adjusted to prolong service life, ensuring low maintenance costs. - Stable Operation:

The dual-motor drive provides strong power and stable operation for heavy-duty tasks.

Product Photos

Technical Parameters

| Model | Feeding Size (mm) | Discharge Size (mm) | Capacity (t/h) | Allowable Moisture Content | Motor Power (kw) | Dimensions (mm) | Weight (t) |

|---|---|---|---|---|---|---|---|

| 2PC600×400 | ≤100 | 2-3mm accounts for 80-90% | 10-15 | <20% | 18.5+18.5 (15) | 2350×926×630 | 1 |

| 2PC600×600 | ≤110 | 15-20 | 22+22 (18.5) | 2875×1300×1650 | 1.3 | ||

| 2PC600×800 | ≤110 | 20-30 | 30+30 (22) | 2400×1360×1600 | 1.8 | ||

| 2PC800×600 | ≤110 | 30-40 | 45+45 (37) | 3625×1314×2065 | 3 | ||

| 2PC800×800 | ≤120 | 40-50 | 55+55 (45) | 3485×1400×2254 | 3.5 | ||

| 2PC1000×800 | ≤120 | 50-60 | 55+75 (55) | 3950×1750×2280 | 5.5 | ||

| 2PC1000×1000 | ≤120 | 60-90 | 90+90 (75) | 4086×2030×2337 | 7 | ||

| 2PC1000×1200 | ≤180 | 70-90 | 110+90 | 3800×2000×2400 | 8 | ||

| 2PC1000×1400 | ≤200 | 100-120 | 110+132 | 3900×2400×2700 | 8.5 | ||

| 2PC1200×1400 | ≤200 | 120-130 | 132+160 | 5900×2658×3210 | 9 | ||

| 2PC1400×1600 | ≤200 | 130-180 | 160+200 | 6000×3100×3900 | 13 |