Product Introduction

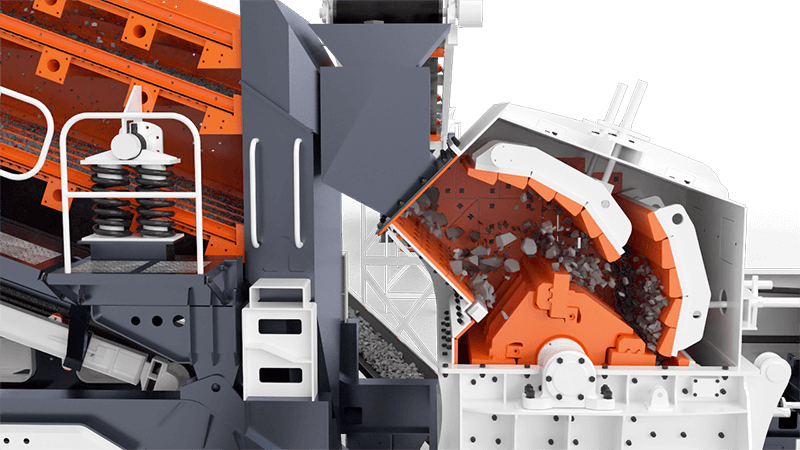

In the application of the mobile crushing station, the two-stage (secondary) and three-stage (tertiary) fine crushing stages are critical. Xianglong’s S-series mobile station combines the high-performance and high-capacity impact crusher or S single-cylinder / HP series cone crusher onto a single, wheeled chassis.

This combination can achieve high productivity, a large crushing ratio, and a better final grain shape. This integrated design has proven to be superior to old-fashioned, fixed crushing lines in terms of performance, efficiency, production capacity, and finished product quality.

Overview of Advantages

- Versatile Application

The system can be configured from a single, stand-alone application to a complex multi-terminal online application, adapting to any project size. - High-Capacity Crushing

Features a large processing capacity thanks to the powerful single-cylinder cone breakage technology. - Adjustable for Efficiency

You can increase the vibration screen installation angle, making the machine and its processing capacity more powerful and efficient. - Customizable Host

Equipped with an adaptive host device, allowing you to switch the main crusher (cone or impact) to meet your customers’ personalized needs. - Fast Deployment

A flexible parking function allows the unit to be quickly set up and enter working mode immediately upon arrival at the site.

Working Principle

Material is fed into the mobile plant and enters the main crushing unit for size reduction. The crushed material is then transported to the onboard vibrating screen, which separates it into different sizes. Finished products are discharged via conveyors, while oversized material is returned to the crusher for further processing in a closed circuit.

Product Photos

Technical Parameters

| Model | Corollary Equipment | Host Model | Feeding Size(mm) | Capacity(t/h) | Transport Dimension(mm) |

|---|---|---|---|---|---|

| S-CS75 | 3YK1848 | CS75 | ≤160 | 59-163 | 12600x2800x4400 |

| S-CS110 | 3YK1860 | CS110 | ≤178 | 100-200 | 13800x3000x4400 |

| S-CS160 | 3YK2160 | CS160 | ≤188 | 132-253 | 13800x3000x4400 |

| S-CS220 | 3YK2160 | CS220 | ≤230 | 215-330 | 14500x3000x4500 |

| S-H420 | 3YK1848 | SH420 | ≤240 | 85-170 | 12600x2900x4400 |

| S-H430 | 3YK1860 | SH430 | ≤360 | 120-345 | 13800x3000x4600 |

| S-H440 | 3YK2160 | SH450 | ≤450 | 255-605 | 14800x3200x4600 |

| S-HP100 | 3YK1860 | SHP100 | ≤140 | 75-140 | 13800x2900x4300 |

| S-HP200 | 3YK2160 | SHP200 | ≤185 | 145-250 | 14200x3000x4500 |

| S-HP300 | 3YK2160 | SHP300 | ≤230 | 220-440 | 16500x3200x4600 |

| S-PF1214 | 3YK1860 | PF1214 | ≤300 | 100-200 | 14500x2900x4500 |

| S-PF1315 | 3YK2160 | PF1315 | ≤350 | 130-280 | 15200x3000x4500 |

| S-PF1320 | 3YK2460 | PF1320 | ≤500 | 180-400 | 15200x3000x4500 |

| S-S1860 | 3YZK1860 | ≤400 | 65-586 | 10500x2700x4200 | |

| S-S2160 | 3YZK2160 | ≤400 | 81-720 | 10500x3000x4500 | |

| S-S2460 | 3YZK2460 | ≤400 | 100-810 | 10500x3200x4500 |