Product Introduction

The CS single-cylinder hydraulic cone crusher is divided into standard and short-headed types, which are used for medium crushing and fine crushing, respectively. It is suitable for crushing all kinds of ores and rocks with medium and above-medium hardness (f=5-16) in metallurgy, construction, highway, railway, water and electricity, transportation, chemistry, and building material industries. It is especially widely used in the crushing of metal ore and construction sand/gravel materials.

Advantages

- Multi-cavity Crushing

Multiple cavity types (from coarse to fine) can be realized on a single machine, requiring only the replacement of the fixed cone (bowl liner) to switch between crushing applications. - High-efficiency Hydraulic, Long Service Life

Adopts a reliable and advanced thin oil lubrication system to ensure improved service life. - Advanced Hydraulic Technology

High-performing hydraulic technology provides both overload protection and hydraulic adjustment of the discharge port (CSS). - Laminating Crushing, Good Particle Shape

Utilizes a special crushing cavity shape and the laminating (inter-particle) crushing principle. This generates crushing action between the particles themselves, significantly increasing the proportion of cubical products, reducing needle/flaky particles, and creating a more uniform granule level. - Simple Structure, Easy Maintenance

The main shaft is supported at both the upper and lower ends, allowing it to withstand greater crushing force and stroke. This design, combined with the special cavity shape, enables higher crushing efficiency.

Working Principle

The motor drives the eccentric sleeve of the crusher to rotate. The moving cone (movable cone) performs a swing motion under the forced action of the eccentric sleeve. The material is continuously squeezed and bent within the crushing cavity, which is composed of the moving cone and the fixed cone (mantle and bowl liner). This process utilizes the laminating crushing principle, where particles are crushed against each other. The crushed material is then discharged from the discharge port at the bottom by its own gravity. The hydraulic system provides overload protection and is used for adjusting the discharge opening.

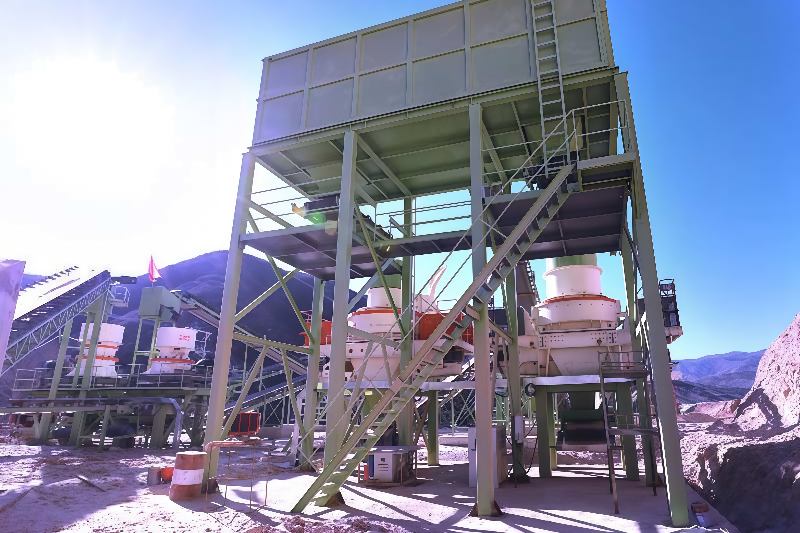

Product Photos

Technical Parameters

| Model | Cavity Type | Max feed inlet Size (mm) | Minimum Discharge Opening (mm) | Capacity (t/h) | Maximum installed power (kw) |

|---|---|---|---|---|---|

| CS420 | S1 Extra coarse | 240 | 22 | 85-170 | 90 |

| S2 Medium coarse | 200 | 19 | 70-130 | ||

| CH420 | H1 Fine | 135 | 10 | 45-130 | |

| H2 Medium fine | 65 | 8 | 35-80 | ||

| H3 Extra fine | 38 | 4 | 27-60 | ||

| CS430 | S1 Extra coarse | 360 | 25 | 120-345 | 160 |

| S2 Medium coarse | 300 | 22 | 105-305 | ||

| S3 Coarse | 235 | 19 | 90-275 | ||

| CH430 | H1 Fine | 185 | 13 | 60-210 | |

| H2 Medium fine | 90 | 10 | 65-165 | ||

| H3 Extra fine | 50 | 6 | 48-105 | ||

| CS440 | S1 Extra coarse | 450 | 35 | 255-605 | 250 |

| S2 Medium coarse | 400 | 29 | 215-515 | ||

| S3 Coarse | 250 | 25 | 190-490 | ||

| CH440 | H1 Fine | 220 | 16 | 110-395 | |

| H2 Medium fine | 110 | 13 | 115-340 | ||

| H3 Extra fine | 70 | 8 | 90-225 | ||

| CS660 | S1 Extra coarse | 560 | 41 | 355-1050 | 315 |

| S2 Medium coarse | 500 | 38 | 305-685 | ||

| CH660 | H1 Fine | 275 | 16 | 170-665 | |

| H2 Medium fine | 135 | 16 | 190-505 | ||

| H3 Extra coarse | 65 | 13 | 205-320 |