What exactly is a jaw crusher?

A jaw crusher is a heavy-duty machine that uses compressive force to break large rocks into smaller pieces. It features a fixed jaw and a moving jaw that squeeze material between them. This machine is primarily used in mining, quarries, and recycling as the first stage of size reduction.

The Working Principle Explained Step-by-Step

So, how does this giant machine actually break massive rocks into smaller pieces?

A jaw crusher works by using compressive force. It features one fixed jaw plate and one moving jaw plate (called a pitman). An eccentric shaft drives the pitman in an elliptical motion, causing it to squeeze rock against the fixed jaw. This repeated compression breaks the material down until it is small enough to fall through the discharge opening at the bottom.

The Core Crushing Action: Compressive Force

The primary principle behind a jaw crusher is simple: compressive force.

Think about squeezing a walnut in a bench vise. The jaw crusher does the same thing, but on a massive, industrial scale. Material (like blasted rock or ore) is trapped between two massive wear plates: the fixed jaw and the movable jaw. The movable jaw then applies immense pressure, forcing the rock to fracture and break.

This method is called “compression crushing.” It is extremely effective for hard, abrasive materials like granite, basalt, or iron ore. Impact-style crushers, by contrast, often wear out too quickly on these same materials. The key is that the rock shatters when the applied pressure exceeds its internal compressive strength.

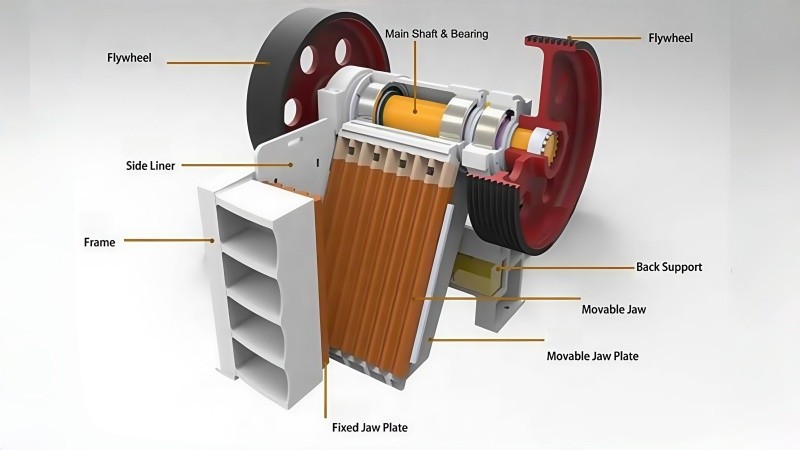

A Step-by-Step Look at the Crushing Cycle

The crushing process isn’t one single squeeze; it’s a continuous, rapid cycle. Let’s follow a single piece of rock on its journey through the V-shaped crushing chamber.

- Feeding: Material is fed into the wide opening at the top of the crusher.

- Compression (The “Stroke”): The moving jaw swings inward and upward, powerfully compressing the rock against the fixed jaw. This intense stroke causes the rock to shatter.

- Release: The moving jaw then swings downward and backward. This release motion allows the now-smaller pieces of material to fall further down into the cavity by gravity.

- Repetition: As the material moves down, it enters a narrower part of the chamber. It is then squeezed again by the next compressive stroke. This cycle repeats multiple times as the rock travels downward.

- Discharge: Finally, the material is crushed small enough to pass through the narrow gap at the very bottom of the jaws. It then falls onto a conveyor belt to be transported away.

The Role of the Eccentric Shaft and Pitman

But what creates this powerful, repeating motion? The answer lies in two key parts working together: the eccentric shaft and the pitman.

- The Eccentric Shaft (The “Crank”): This is the main rotating shaft at the top of the crusher, driven by the large flywheel. It is “eccentric” because its center of rotation is slightly offset from its geometric center.

- The Pitman (The “Moving Jaw”): The pitman is the heavy, moving jaw assembly that is suspended from this eccentric shaft.

As the eccentric shaft spins, it forces the top of the pitman to move in a small circle. This, in turn, causes the bottom of the pitman (where the jaw plate is) to move in an elliptical path.

This elliptical motion is the secret to the jaw crusher’s efficiency. It not only compresses the rock with its in-and-out motion. It also helps to “push” the material down toward the discharge opening with its up-and-down motion. This is known as an aggressive, non-choking crushing action.

Understanding the Close Side Setting (CSS)

One of the most important operational terms for any jaw crusher is the Close Side Setting, or CSS.

The CSS is simply the narrowest gap between the fixed and moving jaw plates at the very bottom of the crushing chamber. It is measured when the moving jaw is at its closest point (the peak of its compressive stroke).

This setting is critical because it directly controls the maximum size of the final product.

For example, a CSS of 3 inches (approx. 75 mm) means that, in theory, no rock larger than 3 inches can exit the crusher. Operators adjust the CSS based on the job’s requirements.

- A smaller (tighter) CSS produces finer material but reduces the machine’s overall throughput (tons per hour).

- A larger (wider) CSS increases throughput but produces a coarser, larger product.

The available adjustment range and the exact product size you will get from a specific setting can vary by model, jaw plate condition, and manufacturer. Because of this, you should always check with the supplier or your machine’s technical manual to confirm the precise adjustment capabilities.

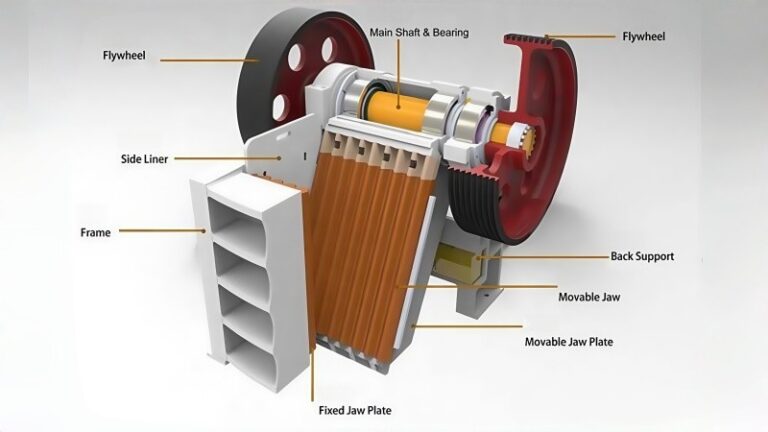

What Are the Key Components You Should Know?

So, what are the main parts that work together to make a jaw crusher so powerful?

The key components of a jaw crusher include the Main Frame (the solid body), the Jaw Plates (fixed and swing, which are the main wear parts), the Eccentric Shaft and Flywheel (which create and smooth out the crushing motion), and the Toggle Plate (which acts as a critical safety fuse).

The Main Frame

The main frame is the heavy-duty steel “backbone” of the entire machine. Think of it as the foundation. Its single most important job is to hold all the other parts in perfect alignment while absorbing the massive, repetitive shock loads and vibrations created during crushing.

This frame is not just a simple box; it’s a highly engineered piece of equipment. It must be incredibly strong to keep from fatiguing or cracking after millions of crushing cycles.

- Cast or Welded Frames: Many standard-duty crushers use a frame that is cast in a foundry or fabricated by welding thick steel plates together.

- Bolted Frames: Premium, heavy-duty crushers (like many CJ-series models) often use a non-welded, bolted-together frame. This advanced design, made of several massive steel sections, eliminates the stresses that welding can create. This makes it exceptionally durable under extreme loads.

The Fixed and Swing Jaw Plates (The Wear Parts)

These are the two plates that actually do the work. They are the “teeth” of the crusher.

- Fixed Jaw Plate: This plate is stationary, bolted securely to the mainframe at the front of the crushing chamber.

- Swing Jaw Plate: This plate is bolted to the moving pitman, and it moves with it to create the squeezing action.

Why They Are “Wear Parts”

These plates are in constant, brutal contact with hard, abrasive rock. They are designed to be replaced. They are “sacrificial” parts, just like the tires on a heavy haul truck. They are meant to wear out so that the more expensive components, like the pitman and the frame, are protected.

The Material: High-Manganese Steel

Jaw plates are almost always made from a special alloy called high-manganese steel (e.g., Mn13Cr2, Mn18Cr2). This material has a unique and valuable property: it work-hardens.

This means that the more it gets hit and impacted by rock, the harder its surface becomes. The surface gets incredibly tough and wear-resistant, while the steel underneath remains ductile (not brittle). This property makes it the perfect material for handling high-impact crushing.

Note: The exact manganese content and the “tooth” profile of the jaw plates can be changed to match the type of rock you are crushing (e.g., hard granite vs. softer limestone). The lifespan of these plates can range from hundreds to thousands of hours. You should always consult your supplier to select the correct jaw plate profile and alloy for your specific application.

The Flywheel and Eccentric Shaft

This is the “engine” of the crusher. It’s what creates the crushing motion.

- Eccentric Shaft: As we covered in the “Working Principle” section, this is the main driveshaft. It’s a massive, forged steel shaft with an offset “lobe” or “eccentric.” As it spins, it creates the elliptical motion that drives the pitman.

- Flywheel: The crusher is driven by a large electric motor. The motor’s belt turns a massive, heavy pulley that also acts as a flywheel. There is often a second flywheel on the other side of the shaft for balance.

The Role of the Flywheel

Crushing rock takes a huge spike of energy (the compression stroke) but very little energy on the return stroke. The motor alone would struggle with these constant power peaks.

The flywheel stores kinetic energy (energy of motion) during the easy part of the cycle (the release). It then releases that stored energy during the difficult compression stroke. This is what gives the crusher the immense power to get through tough rocks without slowing down. It also allows the machine to run smoothly with a much smaller, more efficient electric motor.

The Toggle Plate (The Safety Fuse)

This is one of the most clever and most important parts of the machine. The toggle plate is a simple, replaceable bar or plate (often made of cast iron) located at the bottom-back of the machine. It props the bottom of the pitman against the frame.

A Mechanical Fuse for Protection

The toggle plate’s primary job is to act as a safety fuse.

What happens if something uncrushable, like a piece of steel rebar or a lost excavator tooth, falls into the crusher? The machine cannot break steel. This creates an instant, massive overload that could crack the expensive mainframe or snap the eccentric shaft.

Before that catastrophic failure can happen, the toggle plate is designed to fail first. It will buckle or snap, absorbing the overload and stopping the machine. Replacing the relatively inexpensive toggle plate is significantly cheaper than repairing a destroyed frame. It is the crusher’s most important protection.

What Are the Main Types of Jaw Crushers?

When you’re looking at different jaw crushers, what are the main types you need to know about?

Jaw crushers are primarily classified by their core mechanical design: Single-Toggle or Double-Toggle. The single-toggle is the modern standard, used in over 95% of applications. These are then further classified by product series, such as the traditional PE-series versus the high-performance, heavy-duty CJ-series (European type).

The Core Design: Single-Toggle (The Modern Standard) vs. Double-Toggle (Niche)

The working principle and components we’ve already discussed almost always describe the single-toggle machine. This design is the modern standard for a reason.

- Single-Toggle: In this design, the moving jaw (pitman) is suspended directly on the eccentric shaft. As the shaft spins, it gives the jaw a distinct elliptical (egg-shaped) motion. This motion both compresses the rock and provides an aggressive “pushing” action, which helps force material through the chamber. This results in a very high output, making it the most popular design.

- Double-Toggle: This is the original, older jaw crusher design. In this machine, the moving jaw pivots at the top of the frame and is moved by two “toggle” plates. The eccentric shaft moves the toggles, which then push the bottom of the jaw. This creates a pure back-and-forth swinging motion, with no vertical movement.

Why Is One a “Standard” and One a “Niche”?

The key difference is in the motion. The elliptical motion of the single-toggle is highly productive, but the “rubbing” action can also cause higher wear on the jaw plates.

The pure compression of the double-toggle machine causes much less wear. However, it is a far more complex, heavy, and expensive machine, and its production output is lower.

Because of this, the double-toggle is a “niche” machine. It is only used in very specific applications, such as crushing extremely hard and abrasive materials (like some high-grade iron ores) where the cost of replacing jaw plates every few days is the main concern.

For all other applications—like quarries, aggregate, and recycling—the high-output and simpler design of the single-toggle make it the clear winner.

| Feature | Single-Toggle (The Modern Standard) | Double-Toggle (The Niche) |

|---|---|---|

| Primary Motion | Elliptical (Compress + Push) | Pure Swing (Pure Compression) |

| Output / Capacity | High to Very High | Low to Medium |

| Jaw Plate Wear | Standard | Very Low |

| Common Use | 95% of all applications (aggregate, recycling) | Extremely hard, abrasive materials (e.g., iron ore) |

| Complexity | Simpler, fewer moving parts | More complex, heavier, more parts |

Common Single-Toggle Series: PE (Traditional) vs. CJ (European)

Since you will almost always be looking at single-toggle machines, the more practical distinction you will see in the market is between two main product generations: the PE-series and the CJ-series.

Both are single-toggle crushers, but they represent different levels of engineering and performance.

PE-Series (Traditional)

This is the classic, most common jaw crusher design. It’s a proven, reliable, and cost-effective workhorse.

- Design: Features a simple, robust construction.

- Frame: Often uses a welded frame, which is strong and economical to produce.

- Adjustment: Typically uses shim adjustment for the Close Side Setting (CSS). This means operators manually add or remove thick metal plates (shims) behind the toggle plate to change the gap. It is effective but can be slow.

CJ-Series (European Type)

This is a more recent, heavy-duty evolution of the single-toggle design, built for higher performance and easier operation.

- Design: Engineered for higher throughput and stressful applications.

- Frame: Often uses a bolted, non-welded frame. This design (using massive steel sections bolted with high-strength bolts) is extremely durable and better at handling the stress of crushing very hard rock without cracking.

- Adjustment: Almost always features hydraulic adjustment. An operator can change the CSS in minutes using a hydraulic pump and wedge system, which is much faster, safer, and more precise than using shims.

- Crushing Cavity: Often has a deeper crushing cavity with a steeper angle to improve how it “grips” large feed rock and increase efficiency.

While these are the common classifications, the exact features of a “PE” or “CJ” series can vary. The use of a bolted frame or hydraulic adjustment is a key indicator of a premium machine, but it’s always best to check with the manufacturer for the specific technical details of their models.

Where Are These Crushers Typically Used?

So, given its powerful design, where do you actually see a jaw crusher in action?

A jaw crusher is almost always used as a primary crusher, meaning it handles the first, heavy-duty stage of size reduction. Its main applications are in mining (breaking large, run-of-mine ore), quarries (producing aggregate), and in recycling (processing construction and demolition waste like concrete and asphalt).

Primary Crushing in Mining and Quarries

This is the jaw crusher’s most traditional and essential role. In a mine or quarry, it is the first machine in the entire crushing circuit.

- Handling “Run-of-Mine” (ROM) Feed: After a blast at the quarry face, massive, irregular boulders are created. This raw, unprocessed material is called “Run-of-Mine” or ROM.

- The “Workhorse” of the Circuit: The jaw crusher is the heavy-lifter. Its large feed opening (or “gape”) is designed to accept these massive ROM boulders, which can be over a meter (3-4 feet) wide.

- The Goal: The jaw crusher’s only job here is not to make a final product. Its job is to break these huge rocks down into a more manageable size (e.g., under 6-8 inches, or 150-200 mm). This smaller rock is then fed to the next stage, such as a cone crusher (a secondary crusher), which can work more efficiently.

Think of it as the tool that does the “bulk” work, allowing the more specialized “finishing” tools (like cone crushers) to do their jobs properly.

Processing Rock and Concrete for Aggregate

This is the most common application you’ll see. “Aggregate” is the construction industry’s name for sand, gravel, and crushed stone—the key ingredients in concrete and asphalt (pavement).

- Starts at the Quarry: A quarry’s entire purpose is to produce stone of specific sizes.

- The First Break: The jaw crusher takes the large quarried rock (like granite, basalt, or limestone) and performs the primary break.

- Feeds the Plant: The output from the jaw crusher is then sent to a series of secondary and tertiary crushers (like cone or impact crushers) and screens. This circuit refines the rock and sorts it into the exact sizes needed, such as 3/4-inch stone for concrete or 1/2-inch chips for asphalt.

Without the jaw crusher starting this process, it would be impossible to efficiently produce the massive volumes of aggregate needed for roads, bridges, and buildings.

Recycling Construction and Demolition (C&D) Waste

This is one of the fastest-growing and most impressive uses for a jaw crusher, especially for mobile (track-mounted) models.

When a building is demolished or a road is torn up, it creates a massive amount of waste: broken concrete, bricks, and old asphalt. A jaw crusher is the perfect tool for recycling this material.

The Rebar Advantage

C&D waste, particularly concrete, is full of steel reinforcing bar (rebar). This rebar would destroy many other types of crushers.

- How a Jaw Crusher Handles It: A jaw crusher does not “crush” the steel. As it compresses the concrete, the concrete shatters and falls away. The long, tough steel rebar is simply bent and flattened, passing through the chamber. It is then easily picked off the conveyor belt by a large overband magnet.

- Why Not Other Crushers? An impact crusher, for example, uses high-speed hammers. A piece of rebar would instantly get caught, wrap around the rotor, and cause a catastrophic failure.

The jaw crusher’s tough, low-speed, compressive action makes it uniquely suited to handle this “dirty” and difficult material. It turns worthless concrete rubble into a valuable recycled product called Recycled Concrete Aggregate (RCA), which is then used as a base layer for new roads and construction projects.

How Else Are Jaw Crushers Classified in the Industry?

Beyond the internal mechanics, how are jaw crushers categorized in the real world for different jobs?

In the industry, jaw crushers are also classified in two key practical ways: by their mobility (Stationary vs. Mobile units that move on tracks) and by their model name. This model name, such as ‘PE 900×1200’, is a technical code that reveals the crusher’s function (e.g., ‘PE’ for coarse crushing) and its exact feed opening size (900mm wide by 1200mm long).

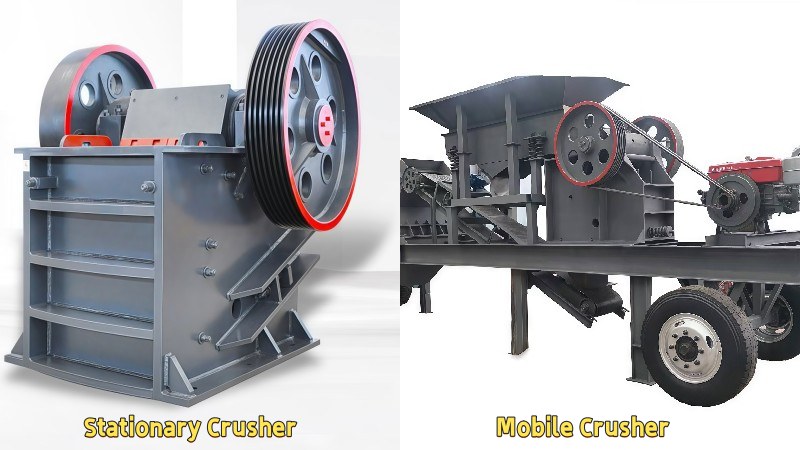

Stationary vs. Mobile Crushers

This is one of the biggest differences you will see in the field. It’s not about the crusher itself, but about how it is deployed.

- Stationary Crushers: These are the traditional, permanent fixtures of a large-scale operation. The jaw crusher is bolted down to a massive concrete foundation or a heavy steel skid-frame. It is one part of a long “assembly line” in a quarry, where rock is brought to it by haul trucks and fed in by a stationary grizzly feeder.

- Mobile Crushers: These units mount the entire plant on a movable chassis for flexibility. Track-mounted models are a “crushing plant on tracks” (like an excavator or dozer) that can be driven around a job site using a remote control. Wheel-mounted (portable) models are built on a chassis with tires and are designed to be towed by a truck between job sites.

This mobility is a game-changer for certain applications. Instead of hauling tons of material to the crusher, a contractor can simply drive the crusher to the pile of material. This is why mobile units are dominant in C&D recycling, where they can move around a demolition site, and in road-building projects.

| Feature | Stationary Crusher | Mobile Crusher (Tracked or Wheeled) |

|---|---|---|

| Setup | Permanent; fixed on a foundation. | Self-contained; can move and operate quickly. |

| Best For | High-volume, long-term quarries and mines. | Contractors, C&D recycling, short-term jobs. |

| Operation | Part of a larger, complex plant. | All-in-one unit; flexible deployment. |

By Model & Size: Understanding PE vs. PEX Series

When you look at a manufacturer’s catalog, you won’t just see “jaw crusher.” You will see specific model names like PE 900×1200. This is not just a random number; it’s the industry’s universal naming code.

This code tells you two critical things: the machine’s function (the letters) and its size (the numbers).

Decoding the Letters (Function)

- PE Series: This stands for a standard Primary (Coarse) crusher. As we discussed in the “Types” section, this is your classic single-toggle jaw. It has a relatively “square-ish” feed opening designed to take the largest possible rocks.

- PEX Series: This stands for a Fine (Secondary) jaw crusher. A PEX model is different. It has a narrow but very long feed opening (e.g., 250mm wide x 1200mm long). It’s not designed to take huge boulders. It’s designed to take smaller material (from a primary crusher) and crush it multiple times as it travels down the long chamber to produce a much finer, smaller product.

Decoding the Numbers (Size)

This is the most important part of the model name. The numbers represent the dimensions of the feed opening (or “gape”) in millimeters.

- Example: PE 900×1200

- 900 = The feed opening is 900 millimeters (0.9m) wide.

- 1200 = The feed opening is 1200 millimeters (1.2m) long.

This instantly tells a quarry manager the maximum size of rock the crusher can theoretically accept. This is the single most important metric for matching a crusher to the rock from the blast site and the required tons per hour.

Important Note: The theoretical gape (e.g., 900×1200) is the “official” size. However, the actual maximum rock size you can feed (known as the “top size”) is usually a bit smaller (e.g., ~750-800mm) to prevent large, blocky rocks from jamming. The actual output tonnage and final product size will always vary based on the rock type, the machine’s speed, and the CSS setting. You should always consult the manufacturer’s specific performance charts for the exact model you are considering.

Conclusion

From its core principle of compression to its critical components like the pitman and toggle plate, the jaw crusher is a simple but powerful machine. Understanding its types (like the single-toggle PE vs. CJ series), its essential uses in quarries and recycling, and how to read its model size (like “PE 900×1200”) gives you a complete picture of this essential primary crusher.