Have you ever wondered what defines a VSI crusher and why it is considered critical for modern aggregate production?

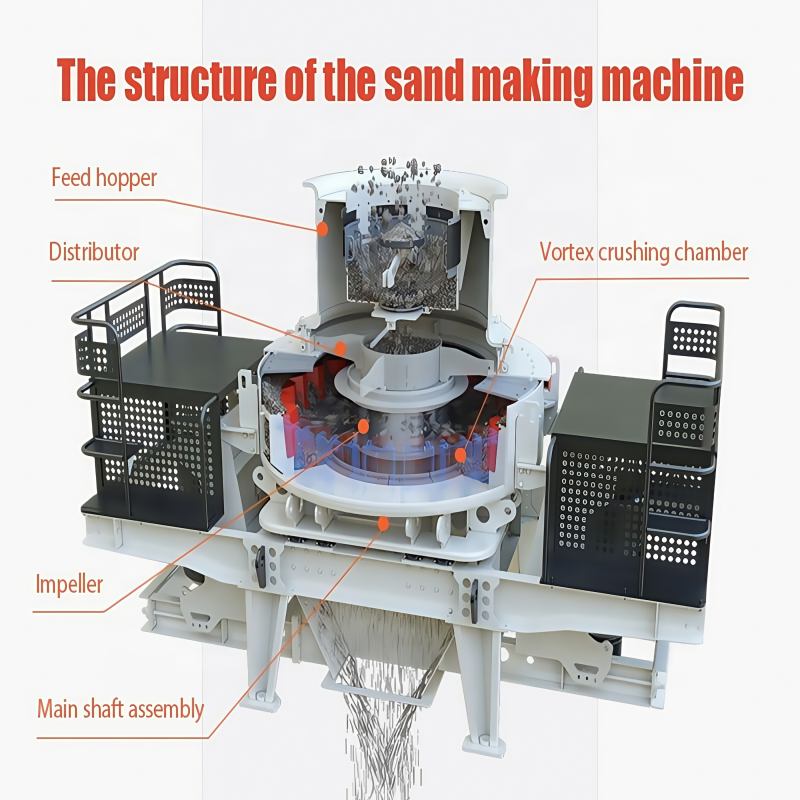

A Vertical Shaft Impact (VSI) crusher is a specialized rock crushing machine that uses a high-speed rotor to accelerate material and throw it against a stationary impact surface. It is primarily used in the tertiary stage of crushing to produce manufactured sand and cubical aggregates by utilizing high-velocity impact energy rather than compression force.

How Exactly Does the VSI Crushing Mechanism Work?

Have you ever wondered what specific mechanical process occurs inside the chamber of a Vertical Shaft Impact crusher to break rocks so effectively?

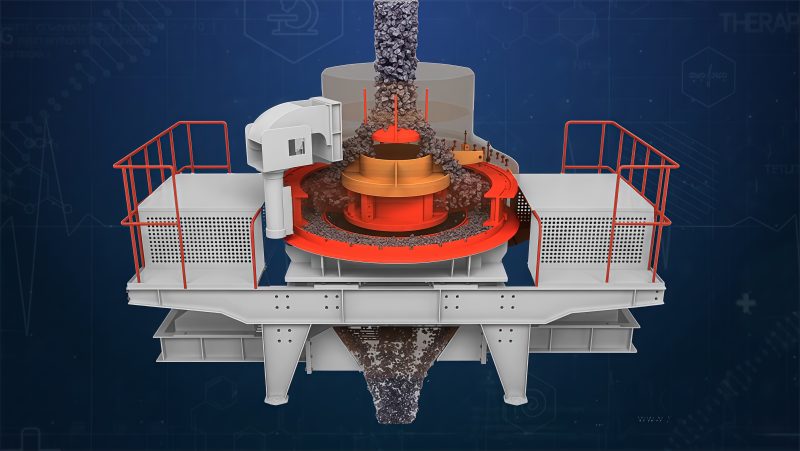

A Vertical Shaft Impact (VSI) crusher operates by feeding material into a high-speed central rotor, which accelerates the rock using strong centrifugal force. This material is then ejected at high velocity against a stationary impact surface, either a rock-lined wall or metallic anvils, causing the stones to shatter due to kinetic energy and impact force rather than compression.

The Central Rotor and Centrifugal Force

The rotor is the heart of the VSI crusher. Unlike the horizontal rotor found in an Impact Crusher (HSI), it acts similarly to a centrifugal pump used in industrial slurry processing, but instead of liquid, it pumps hard stone. The process begins when the feed material drops vertically through a feed tube directly into the center of the rotor.

Once the rock lands on the distributor plate (or cone) inside the rotor, the physics of the machine take over. The rotor spins at very high revolutions per minute (RPM). This rotation generates massive centrifugal force. Consequently, the rock is instantly thrown outward toward the rotor’s periphery.

Inside the rotor, the material travels along specific channels or “ports.” As the stone moves toward the exit ports, its speed increases dramatically. By the time the rock leaves the rotor tips, it reaches velocities typically ranging from 45 to 70 meters per second. This speed is critical because it defines the impact energy.

Note: Rotor tip speeds and RPM settings can vary significantly depending on the manufacturer and the specific model size. Always verify the optimal speed range for your material with your equipment supplier.

Therefore, the rotor does not actually crush the rock itself. Instead, its sole function is to act as a high-powered accelerator. It converts the electrical energy of the motor into the kinetic energy of the flying stone.

Rock-on-Rock (Stone against Stone) Crushing Explained

In the “Rock-on-Rock” (RoR) configuration, the machine uses the stone itself as the breaking surface. This is often called autogenous crushing.

Surrounding the spinning rotor is a crushing chamber. In this setup, a natural build-up of material forms a lining against the chamber wall. We call this the “dead bed” or “rock shelf.” It looks somewhat like a retained bank of stone in a quarry.

When the high-velocity stones eject from the rotor, they do not hit steel. Instead, they crash directly into this stationary bed of rock. The mechanism works as follows:

- The Collision: The flying rock strikes the stationary rock shelf.

- Energy Transfer: The kinetic energy is released instantly, shattering the flying rock along its natural fissures.

- Attrition: The chaotic movement creates a grinding action between particles.

Additionally, many VSI crushers use a “cascade” feeding system. This allows a second stream of material to bypass the rotor and fall in a curtain around it. The high-speed rock from the rotor crashes into this falling curtain. This interaction increases the density of the crushing zone without drawing more power from the motor.

This method mimics an industrial sandblasting process, where particles erode a surface. However, here the goal is to break the particles themselves.

Rock-on-Iron (Stone against Anvil) Configuration Differences

The “Rock-on-Iron” (RoI) configuration changes the target surface. Instead of a bed of stone, the machine uses heavy-duty metallic anvils (also known as breaker plates) mounted around the crushing chamber.

In this mechanical setup, there is no cushioning effect from a rock shelf. The stone leaves the rotor and impacts directly against the hardened steel alloy anvils. Because the steel does not yield like a stone bed might, the impact is much more violent.

This configuration fundamentally changes the crushing dynamics. The stopping distance of the stone is shorter, meaning the shock wave through the material is more intense. As a result, you achieve a higher reduction ratio (the size difference between feed and output) in a single pass.

The following table outlines the mechanical differences between these two configurations:

| Feature | Rock-on-Rock (RoR) | Rock-on-Iron (RoI) |

|---|---|---|

| Impact Surface | Material bed (Dead bed of stone) | Hardened metallic anvils |

| Crushing Action | Impact and attrition (grinding) | High-intensity impact |

| Energy Absorption | Partial absorption by the rock bed | Minimal absorption; high shock |

| Throughput Mechanism | Often uses Cascade feed | Usually direct rotor feed |

| Primary Mechanical Outcome | Shaping and fines production | Size reduction and crushing |

If you are processing abrasive materials like silica, the Rock-on-Iron mechanism will result in rapid wear on the anvils. Therefore, understanding the interaction between the stone’s hardness and the anvil’s metallurgy is vital for operation.

Why is VSI Technology Preferred for Final Shaping and Sand Production?

Why do aggregate producers and civil engineers specifically select Vertical Shaft Impact crushers when they need to produce concrete sand or premium road-base materials?

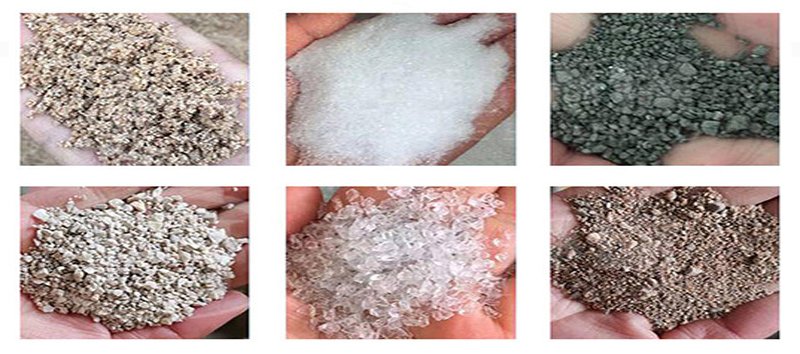

VSI technology is preferred for final shaping and sand production because it utilizes high-velocity impact to break stone along its natural cleavage planes, resulting in a consistent cubical grain shape that increases concrete strength. Unlike compression crushers that can create flat particles, the VSI actively eliminates flakiness and allows operators to precisely manipulate the gradation curve to meet strict specifications for manufactured sand.

Creating High-Quality Cubical Aggregates for Concrete

The primary reason operators use a VSI is to achieve a “cubical” product. In the construction industry, the shape of the stone is just as important as its hardness.

When a VSI crusher impacts rock, the stone shatters along its natural fault lines (cleavage planes). This is scientifically superior to random crushing. The result is a particle that has roughly equal dimensions on all sides, resembling a cube.

Cubical aggregates are superior for the following reasons:

- Better Interlocking: In asphalt mixtures, cubical stones lock together tightly. This prevents the road surface from rutting under heavy traffic.

- Increased Strength: In concrete, cubical stones provide more surface area for the cement paste to bond with.

- Cost Savings: Flaky stones create voids that must be filled with expensive cement. Cubical stones pack densely, reducing the amount of cement binder required to fill the gaps.

Eliminating Flaky and Elongated Particles

Secondary crushers, such as cone crushers, often use compression to break rock. While efficient, this squeezing action can sometimes split the rock into thin, flat shapes. We refer to these as “flaky and elongated” particles.

These flat particles are weak. Under the weight of a building or a truck, they can snap like a thin glass plate. Therefore, strict industry standards, such as ASTM D4791, limit the percentage of these particles allowed in high-grade construction projects.

The VSI acts as a correction machine for these defective shapes. When a flat, elongated stone enters the VSI, it is structurally weaker than a cubical stone. Upon impact, the impact force naturally snaps the flaky particle across its weakest point.

This process transforms a low-quality feed into a premium product. For example, it is common for a VSI to reduce the Flakiness Index of a material from over 30% down to less than 10% in a single pass. This is comparable to a finishing pass in a machining process, where a rough cut is smoothed out to meet final tolerances.

Controlling Gradation for Manufactured Sand (M-Sand)

Natural river sand is becoming scarce and expensive. Consequently, the industry has shifted toward “Manufactured Sand” (M-Sand). According to the U.S. Geological Survey, industrial sand and gravel production is vital for construction, but making high-quality sand is not just about making small rocks; it is about creating the right mix of grain sizes, known as gradation.

The VSI crusher excels here because it offers flexible control over the output size without changing internal hardware. The primary control variable is the rotor speed (RPM).

- Higher Rotor Speed: Increases the impact energy. This creates more “fines” (very small particles like dust and sand).

- Lower Rotor Speed: Reduces the energy. This produces coarser sand and preserves the volume of larger stones.

Furthermore, VSI units often use a “cascade” feed system. This allows operators to flood the crushing chamber with excess material that bypasses the rotor. This material interacts with the high-speed stream, grinding the particles to modify the Fineness Modulus (FM) of the sand.

The table below illustrates how VSI adjustments impact sand production compared to compression crushing:

| Feature | Compression Crushing (e.g., Cone) | VSI Impact Crushing |

|---|---|---|

| Particle Shape | often Angular/Flaky | Highly Cubical |

| Fines Production | Low (produces minimal dust) | High (ideal for sand) |

| Gradation Control | Limited (requires setting change) | Flexible (controlled by RPM) |

| Sand Texture | Smooth surfaces | Rough surface (better bonding) |

By adjusting these variables, a plant manager can produce M-Sand that mimics the gradation of natural river sand, ensuring it meets the strict flow and workability requirements for modern concrete pumping.

When Should You Choose a VSI Over a Cone Crusher?

Are you struggling to decide whether a compression-based machine or an impact-based machine is the right fit for your tertiary crushing stage?

You should choose a VSI over a cone crusher when your primary production goal is improving particle shape (cubicity) and producing manufactured sand, rather than simple size reduction. While cone crushers are generally more energy-efficient for breaking large, hard rocks in secondary stages, VSI crushers are the superior choice for processing abrasive materials with high silica content and for applications requiring precise control over fines gradation.

Impact vs. Compression: Differences in Breaking Principles

The fundamental difference between these two machines lies in the physics they use to break the rock. This physical difference dictates their place in your production line.

A Cone Crusher uses compression. Imagine a heavy-duty industrial hydraulic vise. The machine has a moving mantle that wobbles inside a stationary bowl. As the rock falls in, the mantle squeezes the rock against the wall until it cracks. The rock breaks because the pressure exceeds its compressive strength.

However, compression has a limitation. If the rock has a natural grain or lamination (like slate), the cone crusher might simply split it along those layers. This often results in flat, flaky particles that pass through the machine’s gap without shattering further.

In contrast, a VSI Crusher uses kinetic energy. It does not squeeze; it smashes. As discussed in the mechanism section, the VSI throws the rock at high velocity. The rock fails under tensile stress, which is much lower than compressive stress.

Think of this difference like breaking a ceramic plate.

- Compression (Cone): If you slowly apply pressure to the plate, it might crack into a few large, sharp shards.

- Impact (VSI): If you throw the plate against a hard surface, it shatters instantly into many small, uniform pieces.

Therefore, if your priority is simply making big rocks smaller (reduction ratio), the Cone is efficient. If your priority is “beneficiation”—upgrading the quality and shape of the rock—the VSI is the correct tool.

Comparison of Feed Size Limitations

One of the most critical restrictions you must evaluate is the size of the raw material entering the machine.

Cone crushers are designed to accept relatively large feed materials. A standard secondary cone crusher can easily handle rocks ranging from 200mm to 300mm (8 to 12 inches) depending on the model. They are built with massive steel frames to absorb the force required to crush these large stones.

VSI crushers are significantly more sensitive to feed size. Because the material must pass through a high-speed balanced rotor, the stones must be small enough to fit through the rotor ports without clogging. Generally, the maximum feed size for a VSI is restricted to 40mm to 50mm (1.5 to 2 inches).

Please note: Some oversized “open shoe” rotors or specific large-model VSIs can handle feed sizes up to 70mm or slightly more. Always verify the specific “Max Feed Size” parameter with the manufacturer’s specification sheet for the exact model you are considering.

If you try to feed 150mm rocks into a VSI, you will likely block the rotor intake or cause catastrophic vibration. Therefore, a VSI almost always requires a primary and secondary crusher (like a Jaw or Cone) to work ahead of it to reduce the stone to a manageable size first.

Suitability for Hard and Abrasive Materials

The geological makeup of your stone is often the deciding factor in this comparison. Specifically, you must look at the Abrasiveness Index and Silica (SiO2) content.

Cone crushers rely on manganese steel liners (mantles and concaves) to crush the rock. If you process highly abrasive material—such as river gravel, granite, or quartzite with high silica (SiO2) content—the rock acts like sandpaper. It will wear away the expensive steel liners of a cone crusher very rapidly. In extreme cases, operators might have to change cone liners every few weeks, leading to massive downtime and parts costs.

The VSI, specifically in the Rock-on-Rock configuration, solves this problem.

Since the VSI uses a bed of stone to crush the incoming stone, the abrasive material wears against itself, not against expensive steel parts. The abrasive rock never touches the structural walls of the chamber.

Consequently, for hard, abrasive rocks, the VSI is far more economical in terms of wear costs per ton. The table below summarizes when to apply each machine based on material properties:

| Decision Factor | Cone Crusher | VSI Crusher (Rock-on-Rock) |

|---|---|---|

| Best Application | High reduction ratio (making big rocks small) | Shaping and Sand Production |

| Max Feed Size | Large (up to 300mm+) | Small (typically <50mm) |

| Abrasive Material | High wear costs (steel liners wear out) | Excellent (stone protects the machine) |

| Fine Production | Minimal fines (good for base stone) | High fines (good for sand/asphalt) |

| Energy Efficiency | High (crushes more tons per kW) | Lower (uses more power per ton) |

By analyzing your silica content and feed size, you can determine if the VSI is a necessary addition to your circuit.

Critical Maintenance and Wear Part Considerations

Operators often ask: which specific components require the most attention to keep a VSI crusher running profitably without unexpected downtime?

Critical maintenance for a VSI crusher centers on monitoring high-wear components within the rotor, specifically the tungsten carbide rotor tips and wear plates which endure extreme abrasion. Effective management requires calculating the precise wear cost per ton to ensure profitability and selecting a machine design that features hydraulic lid lifting for rapid, safe access during daily inspections.

Common Wear Components (Rotor Tips and Liners)

The rotor inside a VSI acts like the cutting tool on a high-speed lathe; it makes direct contact with the work material and takes the most abuse. Therefore, specific consumable parts protect the rotor body from being destroyed by the flying stone.

The most critical component is the Rotor Tip. These are small inserts placed at the exit ports of the rotor. Because the stone accelerates to over 60 m/s at this point, the friction is intense. Manufacturers typically make these tips from Tungsten Carbide, an extremely hard metal alloy used in industrial drilling.

Behind the tip, there is usually a Back-up Tip. This acts as a safety net. If the primary tip breaks or wears through completely during a shift, the back-up tip protects the expensive rotor body until you can stop the machine.

Inside the rotor, Wear Plates (top and bottom) line the floor and ceiling of the spinning chamber. These plates protect the steel structure from the sliding rock before it ejects.

Please note: The lifespan of these wear parts is highly dependent on the abrasiveness of your feed material and the alloy quality from your specific supplier. Always consult your parts manual for the exact wear limits.

The table below identifies the primary wear parts and their specific functions:

| Component | Material | Function | Importance |

|---|---|---|---|

| Rotor Tip | Tungsten Carbide | Takes the primary impact at the exit port | Highest wear item; check daily |

| Back-up Tip | Tungsten Carbide | Protects rotor body if primary tip fails | Critical safety redundancy |

| Cavity Wear Plate | Chrome Iron / Steel | Protects rotor floor/roof from sliding rock | Prevents structural rotor damage |

| Feed Tube | High Chrome Iron | Guides rock into the center of the rotor | Takes initial vertical impact |

Understanding Wear Costs per Ton

Buying a VSI crusher is easy, but feeding it wear parts can be expensive if not managed correctly. Operators must track “Wear Cost per Ton.” This is a key performance indicator (KPI).

You calculate this by taking the total cost of a set of wear parts and dividing it by the total tons of material processed before those parts needed replacement.

For example, imagine a set of rotor tips costs $1,000.

- Scenario A: You crush soft limestone. The tips last for 50,000 tons.

- Calculation: $1,000 / 50,000 = $0.02 per ton. This is very cheap.

- Scenario B: You crush abrasive river gravel. The tips last for only 2,000 tons.

- Calculation: $1,000 / 2,000 = $0.50 per ton. This is a significant operational cost.

Understanding this metric helps you decide whether to use “Rock-on-Rock” or “Rock-on-Iron.” As mentioned earlier, “Rock-on-Rock” uses the stone to protect the machine, which drastically lowers this wear cost per ton when processing abrasive materials. If your wear costs exceed your profit margin, you may need to adjust your rotor speed or feed rate.

Accessibility and Ease of Replacement

Since VSI crushers operate at high speeds, the rotor must remain perfectly balanced. Even a small amount of uneven wear can cause dangerous vibrations. Consequently, maintenance teams must inspect the rotor frequently—often daily.

Because inspections are frequent, accessibility is a major design consideration. Modern VSI crushers feature a hydraulic lid lifter.

Historically, accessing the crushing chamber required an overhead crane to lift the heavy top section, a process that was slow and posed safety risks. Modern hydraulic systems lift and rotate the lid automatically, turning a dangerous, labor-intensive task into a simple button-press operation. This allows operators to access the chamber in less than two minutes.

Furthermore, the design of the wear parts themselves affects downtime. The best rotors use a modular, quick-release system for the tips. This allows a technician to swap out a worn tip using basic hand tools in just a few minutes, without the need for welding or complex dismantling.

If the machine is difficult to open, operators might skip daily inspections. This negligence can lead to catastrophic rotor failure. Therefore, ease of access is not just a luxury; it is a vital component of long-term machine reliability.

Conclusion

Choosing the right equipment for your crushing circuit requires understanding not just the machine’s capacity, but its specific role in the quality of your final product. The Vertical Shaft Impact (VSI) crusher stands out as the premier solution for producing cubical, stress-free aggregates and high-quality manufactured sand (M-Sand).

By leveraging the physics of high-velocity impact, the VSI corrects the flaws left by compression crushers, ensuring your material meets the strict standards of modern concrete and asphalt industries. While it requires careful management of feed size and wear parts, its ability to process abrasive materials efficiently through “Rock-on-Rock” technology makes it an indispensable asset for aggregate producers aiming for quality and profitability.