What exactly is a cone crusher and what does it do?

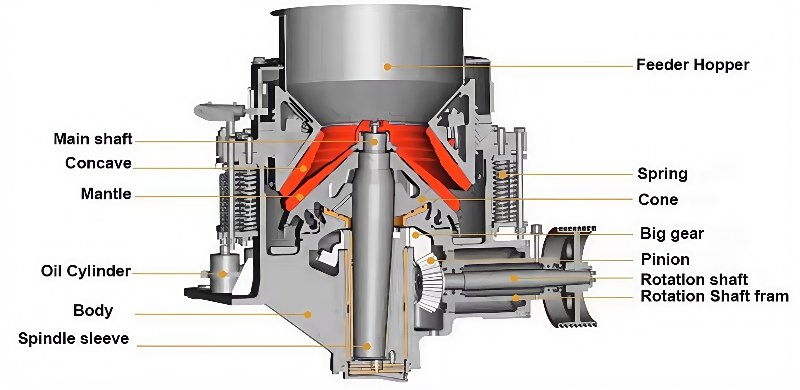

A cone crusher is a type of compression-style crushing machine designed to break down hard, abrasive rock into smaller, finer material. It works by squeezing rock between an eccentrically gyrating (moving) steel cone, called the mantle, and a stationary steel bowl, known as the concave. It is primarily used in the secondary and tertiary stages of crushing in mining, aggregate, and quarrying operations.

How Exactly Does It Crush Rock?

So, how does this heavy piece of equipment actually break down massive rocks?

A cone crusher works by squeezing rock between two hardened steel surfaces. It uses a method called “compression crushing.” An eccentrically rotating (offset) main shaft causes a moving steel cone, called the mantle, to gyrate inside a stationary steel bowl, called the concave. As rock enters the top, it gets pinched and broken in the narrowing gap between the two surfaces.

The Principle of Eccentric Motion

The heart of the cone crusher is its eccentric motion. But what does that mean?

Imagine the main shaft that drives the crusher. It doesn’t spin perfectly in the center like a simple drill. Instead, its drive bearing is mounted slightly off-center, or “eccentrically.”

As the drive motor spins this shaft, the off-center mounting forces the entire crushing head to move in a constant, wobbling circle. This specific “wobble” is called gyration. This motion is the key. It is not a simple spinning action, and it’s not a back-and-forth jaw action like in a jaw crusher. It is a continuous, rolling squeeze.

The speed of this gyration, measured in RPM (revolutions per minute), is a critical setting. A faster speed can create finer material but also affects wear and power draw. Because this speed is precisely engineered for the machine’s cavity, it’s always best to consult the manufacturer’s specifications for the optimal range.

Inside the Crushing Chamber (Mantle and Concave)

The crushing action happens in a V-shaped area called the crushing chamber. This chamber is the gap formed between two pieces of high-strength manganese steel:

- The Mantle: This is the inner, cone-shaped steel piece that moves. It’s the “moving cone” and is mounted on the gyrating head.

- The Concave (or Bowl Liner): This is the outer, stationary steel piece that lines the upper frame of the crusher. It’s the “fixed cone.”

As the mantle gyrates, it “rolls” around the inner wall of the concave. This means at any given moment, one side of the chamber is squeezing shut (the “crushing” side), while the exact opposite side is opening up (the “intake” side). This simultaneous action is what makes the cone crusher so efficient and allows for a continuous flow of material.

A Step-by-Step Look at the Crushing Action

Let’s follow a single rock’s journey to see how this all comes together.

- Step 1: Feed Enters the Top

Large, pre-crushed rock (usually from a primary jaw crusher) is fed into the top of the open chamber. As the mantle moves away on the intake side, the rock falls down into the gap. - Step 2: The First Squeeze (Compression)

The gyrating mantle then “rolls” toward the rock, closing the gap. The rock is squeezed and fractured between the mantle and concave. This is a pure compression crush, which is extremely effective for hard, abrasive materials like granite or basalt. - Step 3: Release and Fall

As the mantle continues its gyration, it moves away from the broken pieces. The gap opens, and gravity causes the smaller fragments to fall further down into the narrower part of the chamber. - Step 4: Repeated Crushing (Inter-Particle Crushing)

This process repeats multiple times as the material moves down. A key process, known as inter-particle crushing, also happens here. In a properly “choke-fed” crusher (where the chamber is kept full), rocks are not just crushed against the steel; they are crushed against each other. This action is what creates the high-quality, cubical-shaped final product that is so valued in concrete and asphalt production. - Step 5: Discharge at the Bottom

Once the particles are small enough to fit through the narrowest gap at the bottom, they fall out of the crusher. This final gap size is known as the Closed Side Setting (CSS), which is the key adjustable setting that determines the size of the final product.

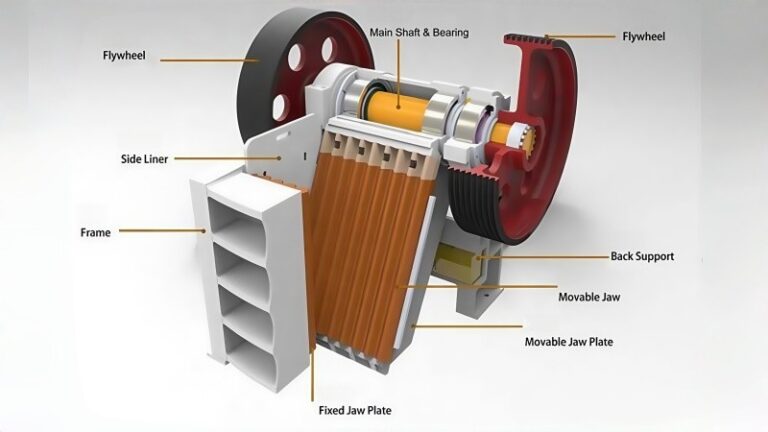

What Are the Main Components I Should Know?

When you look at a cone crusher, what are the essential parts that make it work?

The four main components of a cone crusher are the mantle, the concave (or bowl liner), the eccentric shaft and drive, and the setting adjustment system. The mantle and concave are the two hardened steel liners that perform the actual crushing. The eccentric shaft provides the unique gyrating motion, and the adjustment system controls the final product size.

The Mantle (The Moving Crushing Surface)

The mantle is the inner, cone-shaped steel piece that moves. It’s mounted on the main head, which is forced to gyrate by the drive system.

Think of the mantle as the “crushing tool.” It is a sacrificial wear liner, meaning it is designed to be completely replaced after its service life. It is not part of the crusher’s permanent structure.

- Material: It is almost always made from high-manganese steel.

- Why Manganese? This special metal has a unique property called “work-hardening.” This means that as rocks repeatedly impact its surface, the steel actually gets tougher and more resistant to wear.

- Role: As the mantle gyrates, it squeezes the rock against the stationary liner (the concave).

The Concave or Bowl Liner (The Stationary Crushing Surface)

The concave, sometimes called the bowl liner, is the outer, stationary cone-shaped steel piece. It lines the upper frame (or bowl) of the crusher and faces the mantle.

The concave and the mantle work together as a set. The V-shaped gap between them is the crushing chamber.

- Material: Like the mantle, the concave is also a manganese steel wear liner designed for replacement.

- Role: It provides the fixed, solid “wall” for the mantle to crush against.

- Relationship: In short:

- Mantle: The inner, moving wear liner.

- Concave: The outer, stationary wear liner.

The shape and profile of these two liners are precisely engineered. A “coarse” cavity for larger rock will have a different shape than a “fine” cavity for producing sand, even on the same machine.

The Eccentric Shaft and Drive

If the mantle is the tool, the eccentric shaft and drive are the “engine” that moves it. This system is responsible for creating the unique gyration motion we discussed earlier.

It’s not just a simple spinning shaft. The power flows through several key parts:

- The Motor and Pulley: An external electric motor turns a drive belt and pulley.

- Pinion and Bevel Gear: This pulley spins a small pinion gear, which in turn rotates a large, horizontal bevel gear located at the bottom of the crusher.

- The Eccentric Assembly: This is the most important part. The main shaft sits inside an eccentric sleeve (or bushing) that is mounted off-center from the bevel gear’s true center.

As the bevel gear spins, this off-center sleeve forces the main shaft to “wobble” in a precise circle, creating the gyration. This system translates the high-speed rotation from the motor into a low-speed, high-power crushing force.

The Setting Adjustment System (CSS)

This is perhaps the most important operational part of the crusher. The Setting Adjustment System is the mechanism that controls the final size of your crushed product.

It does this by changing the Closed Side Setting (CSS).

What is CSS? The Closed Side Setting is the distance, or gap, between the mantle and the concave at the narrowest point at the bottom of the chamber.

A small CSS (e.g., 1/2 inch) will produce a very fine, small product. A large CSS (e.g., 1.5 inches) will produce a coarser, larger product.

The adjustment system works by physically raising or lowering the entire upper assembly (the bowl and its concave liner).

- To get a smaller product (finer): The system lowers the bowl, bringing the concave closer to the mantle.

- To get a larger product (coarser): The system raises the bowl, moving the concave away from the mantle.

The way this adjustment is made (e.g., using springs, hydraulic rams) is what defines the different types of cone crushers, which we will cover in the next section. The available CSS range and adjustment method can vary significantly between manufacturers, so it’s always important to check the specific machine’s operational manual.

What Are the Real Differences Between Crusher Types?

When you see terms like “Spring,” “Compound,” or “Multi-Cylinder,” what do they actually mean?

The main differences between cone crusher types are their overload protection and adjustment systems. Classic Spring crushers use large springs for protection and manual adjustment. Compound (Hybrid) crushers also use springs for protection but add hydraulics for adjustment and clearing. Modern Full Hydraulic crushers use hydraulic cylinders for protection, adjustment, and clearing, with Single-Cylinder and Multi-Cylinder being the two main designs.

Type 1: The Classic Spring Cone Crusher

This is the original, classic design, famously represented by the Symons cone crusher. Its operation is simple and robust.

- Overload Protection: Its “safety system” is a set of large, powerful coil springs mounted on the outside of the crusher. If a piece of uncrushable material, like a steel bolt (called “tramp iron”), enters the chamber, the entire crushing bowl assembly is forced to lift up. This action compresses the springs, which opens the gap and allows the iron to pass through safely. Once it’s gone, the springs force the bowl back down into position.

- Adjustment: This is the main drawback. To change the product size (the CSS), operators must shut the machine down. They often use manual or semi-automatic (jack-assisted) systems to rotate the heavy adjustment ring, which is a slow and labor-intensive process.

Type 2: The Compound (Hybrid) Cone Crusher (Spring Protection + Hydraulic Controls)

This type is a smart upgrade to the classic spring model. It fixes the biggest operational headaches while keeping the core protection system.

- Overload Protection: It still uses springs as the primary safety net. When tramp iron enters, the springs compress, just like in the classic model.

- Hydraulic Controls: This is the “hybrid” part. It adds a hydraulic system for two key convenience features:

- Hydraulic Adjustment: Operators can adjust the CSS (product size) remotely. A hydraulic motor rotates the adjustment ring, making changes fast and easy without stopping production.

- Hydraulic Clearing: If the crusher becomes “choked” (plugged with material), the hydraulic system can lift the entire upper assembly. This “clears” the chamber in minutes, saving hours of downtime compared to digging it out by hand.

It’s a transitional design that combines the proven, simple protection of springs with the modern efficiency of hydraulic controls.

Type 3: The Modern Full Hydraulic Cone Crusher

This is the modern standard, where hydraulics have completely replaced the springs for all major functions.

- Overload Protection: There are no springs. Instead, one or more powerful hydraulic cylinders (backed by an accumulator, or nitrogen-filled tank) hold the crushing head in place. When tramp iron enters, the pressure spike is instantly relieved as hydraulic fluid is forced into the accumulator. This allows the head (or bowl) to drop or lift, letting the iron pass. The system then automatically resets itself.

- Adjustment & Clearing: The same hydraulic system provides push-button control over both CSS adjustment and cavity clearing, all from the main control room.

Within this category, there are two main architectures:

Single-Cylinder vs. Multi-Cylinder Explained

- Single-Cylinder: This design uses one large hydraulic cylinder located at the bottom of the crusher. This single ram does three jobs: it supports the main shaft, it provides overload protection, and it raises or lowers the entire shaft assembly to adjust the CSS.

- Multi-Cylinder: This design uses several hydraulic cylinders (e.g., 3, 4, or 6) mounted on the outside of the main frame. These cylinders hold the bowl assembly down. They provide the overload protection (by letting the bowl lift up) and also raise the bowl for adjustment and clearing. These machines are known for very stable operation and producing excellent product shape (cubicity).

Classification by Cavity: Standard (Coarse) vs. Short Head (Fine)

This final classification is different. It’s not about the machine’s mechanics (like springs vs. hydraulics) but about its job or application. Both spring and hydraulic models can be built with different cavities.

Think of the “cavity” as the specific shape of the mantle and concave liners.

| Feature | Standard (Coarse) Cavity | Short Head (Fine) Cavity |

|---|---|---|

| Primary Job | Secondary Crushing (e.g., after a jaw crusher) | Tertiary or Quaternary Crushing (fines/sand) |

| Feed Size | Accepts larger rock | Requires smaller, pre-crushed feed |

| Chamber Shape | Wider at the top, steeper cone | Narrower chamber, flatter cone |

| Parallel Zone | Shorter “parallel zone” (the narrowest part) | Longer “parallel zone” for more crushing action |

| Output Size | Coarser product (e.g., 1 to 3 inches) | Finer product (e.g., 3/4 inch down to sand) |

Where Is a Cone Crusher Used in a Crushing Plant?

So, in a big, complex crushing plant, where does the cone crusher actually fit in?

A cone crusher is almost never used at the beginning of the process. It is a workhorse for the middle and final stages of crushing. Its main job is to take large, pre-crushed rock and make it much smaller, operating as the main secondary or tertiary crusher in a circuit, especially when dealing with very hard or abrasive materials.

Its Role as a Secondary and Tertiary Crusher

A crushing plant reduces rock in distinct stages. This staged-reduction process is fundamental to efficient operation. A cone crusher is a key player in this process, but it is not the machine that starts the job.

The Crushing Stages

- Stage 1: Primary Crushing

This first step is for handling the huge boulders taken directly from the quarry. This job is reserved for a Jaw Crusher or a large Primary Gyratory Crusher. They take material as large as 2-3 feet and break it down to a more manageable size, like 6-8 inches. - Stage 2: Secondary Crushing

This is the cone crusher’s first job. The 6-8 inch rock from the primary crusher is fed into a cone crusher (often a “Standard” or “Coarse” cavity model). This crusher’s task is to reduce that rock down to a size like 1.5-3 inches. - Stage 3: Tertiary Crushing

This is the final sizing stage. The material from the secondary crusher is fed into another cone crusher (usually a “Short Head” or “Fine” cavity model). This machine crushes it down to the final, sellable product size, such as 3/4 inch, 1/2 inch, or even smaller for making sand.

Working in a “Closed Circuit”

A cone crusher rarely works alone. It is almost always part of a “closed circuit” to guarantee product size.

- The crusher feeds all its material onto a vibrating screen.

- The screen acts like a filter. Rock that is the correct, finished size (e.g., 3/4 inch) falls through and goes to a stockpile.

- Rock that is still too big (called “oversize”) is sent back to the same cone crusher on a return conveyor belt.

- This material is crushed again and again until it is small enough to pass through the screen. This process is the industry standard for creating a precise, high-quality final product.

Handling Hard and Abrasive Materials

A cone crusher is not the right tool for every rock. Its specialty is crushing materials that are hard and abrasive.

What does this mean?

- Hardness: Materials like granite, basalt, quartzite, and hard river gravel are extremely hard.

- Abrasiveness: These materials act like sandpaper, quickly wearing down any steel they touch.

The reason a cone crusher excels here is its compression crushing method. It squeezes the rock until it breaks.

Compression vs. Impact: A Key Industry Choice

The main alternative to a cone crusher is an Impactor (HSI), which uses high-speed spinning hammers to smash the rock.

- For soft rock (like limestone): An impactor is excellent. It’s efficient and the wear on its parts (blow bars) is manageable.

- For hard rock (like granite): An impactor is a bad choice. A quarry operator crushing granite with an HSI might find their expensive wear parts are completely destroyed in less than a day.

- For hard rock (a cone crusher): This is the correct choice. The cone crusher’s slow, powerful squeeze is far more efficient. Its manganese steel wear parts are designed for this abrasion and can last for weeks or months, resulting in a much lower cost-per-ton.

Key Industries: Mining, Aggregates, and Quarrying

You will find cone crushers at the center of three main industries:

- Aggregates and Quarrying

This is the most common use. These operations produce the crushed stone (aggregates) used to make concrete for roads, bridges, and buildings, and asphalt for paving. These customers demand very specific sizes (e.g., “1/2-inch clean stone”), and the cone crusher’s adjustability makes it perfect for hitting these targets. - Mining

In large-scale mining operations (iron, copper, gold, etc.), cone crushers are used in massive numbers. Their job is to crush the hard ore into smaller pieces. The goal here is “liberation”—breaking the rock small enough to be sent to a milling circuit (like a ball mill), which grinds it into a fine powder to extract the valuable minerals. - Recycling

This is a growing field. Cone crushers are used to process recycled concrete and recycled asphalt (RAP). Their robust overload systems are critical here, as they can handle the stray rebar and other “tramp metal” often found in demolition debris without destroying the machine.

Why Choose a Cone Crusher Over Other Machines?

With other types of crushers out there, why would a quarry owner specifically choose a cone crusher?

A cone crusher is chosen for its superior ability to create high-quality, cubical-shaped stone from very hard and abrasive rock. Its design is highly efficient for secondary and tertiary crushing, delivering a high volume of product and a lower cost-per-ton in materials like granite, basalt, or river gravel, where other crushers would wear out too quickly.

Key Advantage: Creating Cubical-Shaped Products

This is often the most important reason for choosing a cone crusher. The final shape of the crushed stone, known as its cubicity, is critical.

- Why Shape Matters: Customers who buy aggregate for concrete and asphalt have strict quality standards. They demand “cubical” or “equidimensional” stone (like a small cube or ball).

- The Problem with Bad Shapes: Flat, flaky, or elongated particles (like slivers or chips) are weak. They create voids and weak points in concrete or asphalt, leading to a final product that can crack or fail.

- The Cone CrusVher Solution: A cone crusher excels at creating this valuable cubical shape. This is especially true when it is “choke-fed” (kept full of material). When the chamber is full, rocks are crushed against each other, not just against the steel. This “inter-particle crushing” action breaks the stone along its natural internal lines, resulting in a strong, cubical product.

While an impact crusher can also produce good cubical shape, it cannot handle the hard, abrasive rock that a cone crusher is built for.

Key Advantage: High Efficiency and Throughput

A cone crusher is a highly efficient machine, which translates directly to a lower cost-per-ton for the operator.

Power and Wear Cost

In the world of quarrying, efficiency means low wear. A cone crusher’s “squeezing” compression action is ideal for hard rock.

Let’s look at a common case: crushing hard granite.

- If you use an Impact Crusher (HSI): The high-speed hammers (blow bars) would smash against the granite. The extreme abrasion would likely wear out the expensive blow bars in just a few days or, in some cases, hours. This means constant downtime and high parts costs.

- If you use a Cone Crusher: The manganese steel liners are designed for this. They slowly squeeze the rock. These wear parts can last for weeks or even months in the same application.

As a result, the cone crusher has significantly less downtime and a much lower wear cost for every ton of rock it produces.

Continuous Throughput

A cone crusher is not a batch machine. It is a continuous-flow machine designed to process a high volume of material, measured in hundreds of tons per hour. Its gyrating motion allows for a constant intake and discharge of rock, making it the workhorse of a high-production plant.

Comparison: Cone Crusher vs. Gyratory Crusher

This is a common point of confusion because a gyratory crusher looks like a cone crusher and uses the same crushing motion.

The simplest way to think about it is by their job:

- A Primary Gyratory Crusher is like a Jaw Crusher. It’s a Primary crusher.

- A Cone Crusher is a Secondary or Tertiary crusher.

Here is a direct comparison:

| Feature | Primary Gyratory Crusher | Cone Crusher |

|---|---|---|

| Crushing Stage | Primary | Secondary, Tertiary, or Quaternary |

| Feed Size | Massive. Accepts huge boulders (e.g., 40-60 inches). | Small. Needs pre-crushed feed (e.g., 6-10 inches). |

| Physical Size | Enormous. Often taller than a multi-story building. | Much smaller and more compact. |

| Main Shaft | Very long, suspended from a top “spider” assembly. | Shorter, supported from the bottom eccentric drive. |

| Application | High-volume mines and very large quarries. | Most quarries, aggregate plants, and mining. |

Common Limitations to Consider

A cone crusher is a specialized tool, and it is not the right choice for every application.

- It Cannot Handle “Dirty” Feed

The biggest limitation is that cone crushers do not work well with “sticky” or “dirty” material. If the feed rock is mixed with a high amount of clay, dirt, or wet fine particles, this material will pack together inside the crushing chamber. This condition, known as “pancaking,” stops all crushing and requires a full shutdown to clean out. - It Cannot Be a Primary Crusher

With rare exceptions, a cone crusher cannot be fed directly from a quarry. Its feed opening is too small for the large boulders. It must be fed smaller, pre-crushed material from a primary jaw or gyratory crusher. - It Does Not Like “Tramp” Material

Cone crushers are designed for rock. While they have protection systems for the occasional uncrushable piece of metal (tramp iron), they are not designed to handle a steady diet of it. In recycling applications, for example, a strong magnet to remove rebar before the crusher is essential to prevent damage.

Conclusion

From its core principle of eccentric motion to its vital role in the aggregate and mining industries, the cone crusher is an essential piece of equipment. Understanding its main components—the mantle, concave, and drive system—is key. But most importantly, knowing the difference between classic Spring, hybrid Compound, and modern Hydraulic models (like Single-Cylinder and Multi-Cylinder) allows operators to select the perfect machine for the job: efficiently creating high-quality, cubical stone from the toughest rock.